Functional model

Safety Sensor Demonstrator

for safe distance measurement

Trade show booth for the SPS trade fair in Nuremberg

Precision in action - Safe distance measurement

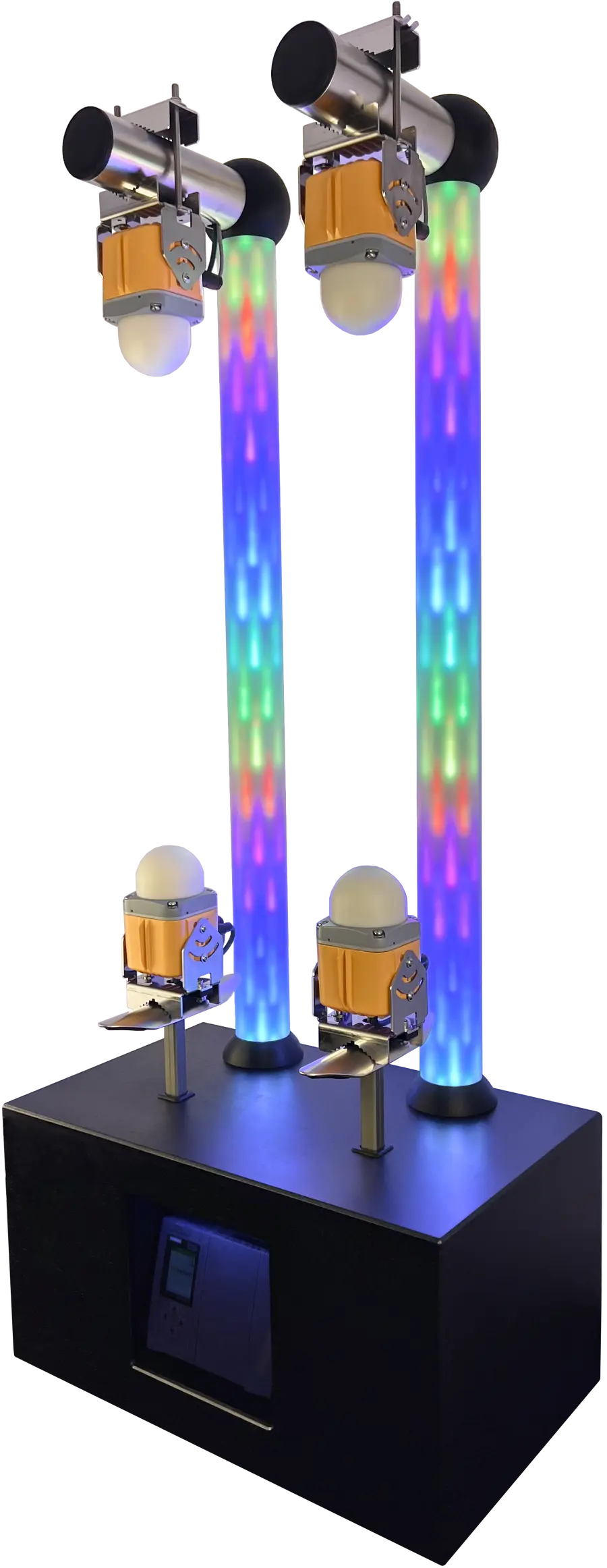

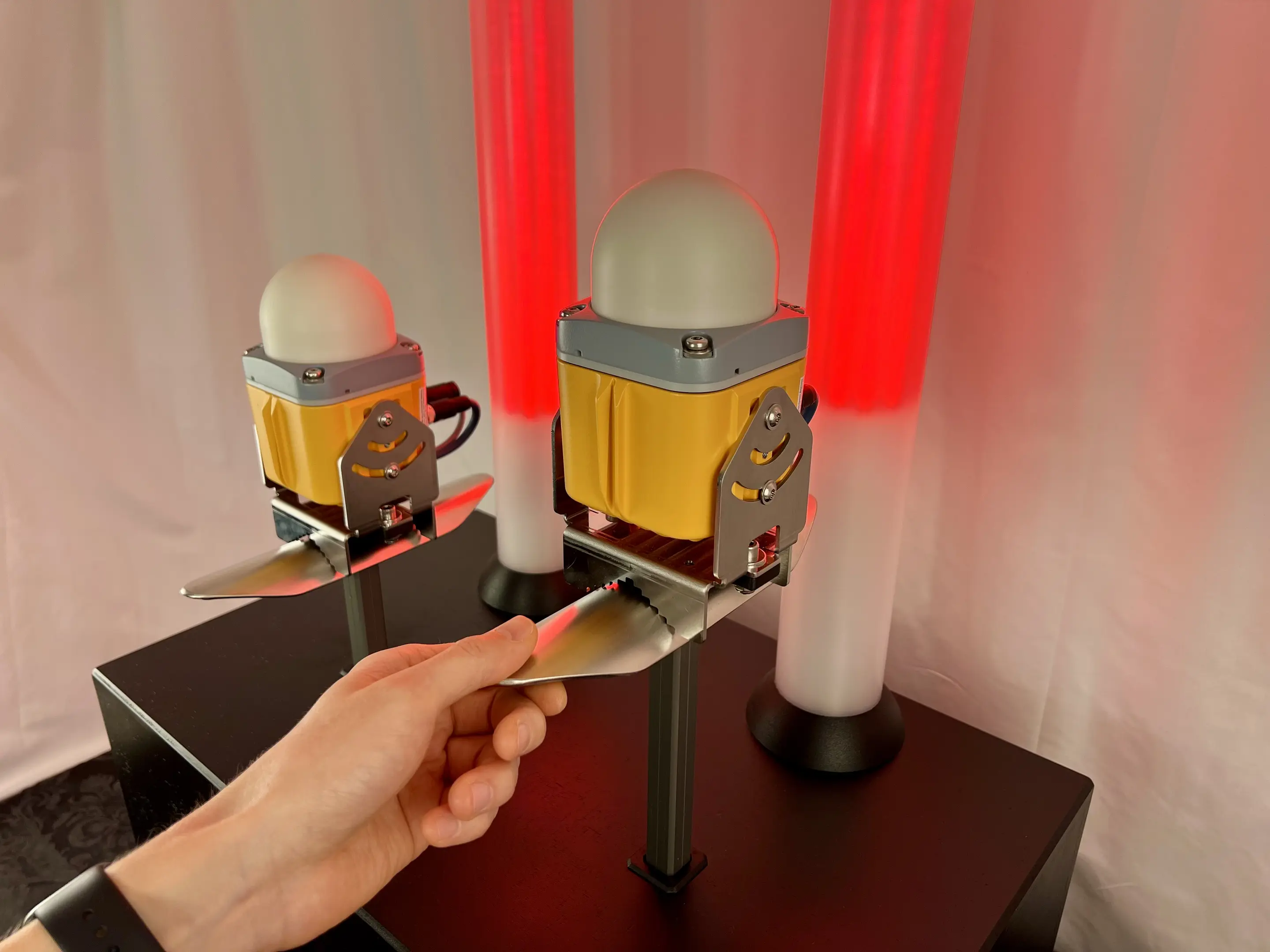

The trade show demonstrator attracts visitors' attention with over 3,000 installed LEDs and illustrates the operating principle of safe distance measurement using a redundantly implemented radar measurement path. Pre-programmed games and mechanically adjustable sensors invite visitors to discover the advantages of radar technology interactively.

Functional model for safety sensor with LED stripes - SPS Trade Fair Nuremberg - Exhibition construction

💡️ Precision in action. The trade show demonstrator attracts visitors' attention with über 3.000 installed LEDs and illustrates the operating principle of safe distance measurement using a redundantly implemented radar measurement path. Pre-programmed games and mechanically adjustable sensors invite visitors to discover the advantages of radar technology interactively.

https://ingenieur-glaser.de/safety-demonstrator/ – Behind the scenes

#FunctionalModel #TradeShowExhibit #TradeShowModel #TradeShow #SpsFair #ExhibitionConstruction #ExhibitionBooth

🧲 Ooh, Aah, Wow! - Customer magnets for your exhibition stand.

The engineering office Glaser develops and manufactures **custom trade show exhibits**. As eye-catchers, they draw visitors' attention to your booth with a curious **“Ooh”**. The benefits of your product are made clear and tangible at the demonstration model with an astonished **“Aah”**. With a concluding **“Wow!”** you, your product and your brand will stay in people’s minds.

https://ingenieur-glaser.de/messebau/ – Trade show exhibits

💡️ Development & Manufacturing – Engineering office Glaser

https://ingenieur-glaser.de/ – Electronics・Software・Hardware

🔔 Don’t miss any developments. Subscribe now!

https://ingenieur-glaser.de/Instagram/ – Instagram

https://ingenieur-glaser.de/Facebook/ – Facebook

https://ingenieur-glaser.de/YouTube/ – YouTube

https://ingenieur-glaser.de/LinkedIn/ – LinkedIn

https://ingenieur-glaser.de/TikTok/ – TikTok

https://ingenieur-glaser.de/Xing/ – Xing

🥇 How visions became successes.

https://ingenieur-glaser.de/Projekte/ – References

📞 Has the spark ignited?

https://ingenieur-glaser.de/Kontakt/ – Contact

#FunctionalModel #TradeShowExhibit #TradeShowModel #TradeShow #SpsFair #ExhibitionConstruction #ExhibitionBooth

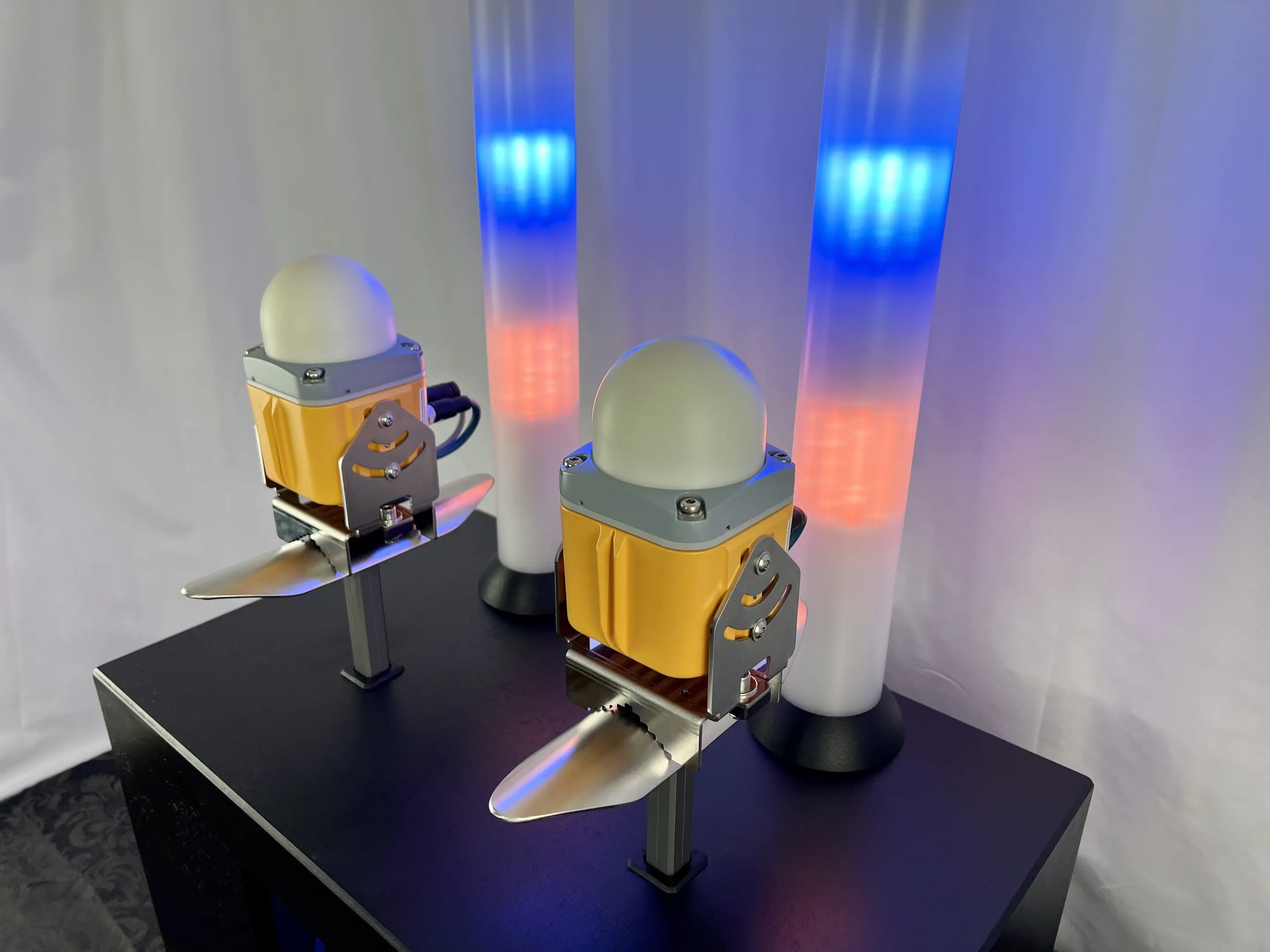

Operating principle - More safety through dual-channel measuring system

For safe distance measurement, two sensor pairs, each composed of two opposing radar sensors, form a self-monitoring measurement system. When the two lower sensors move in parallel they deliver matching and thus valid distance values. If the difference between the measured values becomes too large, an alarm is triggered automatically and the system is immediately brought to a safe state.

Application area - Portal crane for loading container ships

The LPR®-1DHP-291 sensors from SYMEO are used in demanding industrial environments where high robustness and reliability are crucial, for example with dust, dirt and extreme weather conditions.

One example is use in shipyards. Mounted on the crane bridge, the sensors detect and monitor the precise crane position during loading of container ships and ensure the safety of people and equipment under extreme conditions.

Visualization - LED tubes make measured data visible

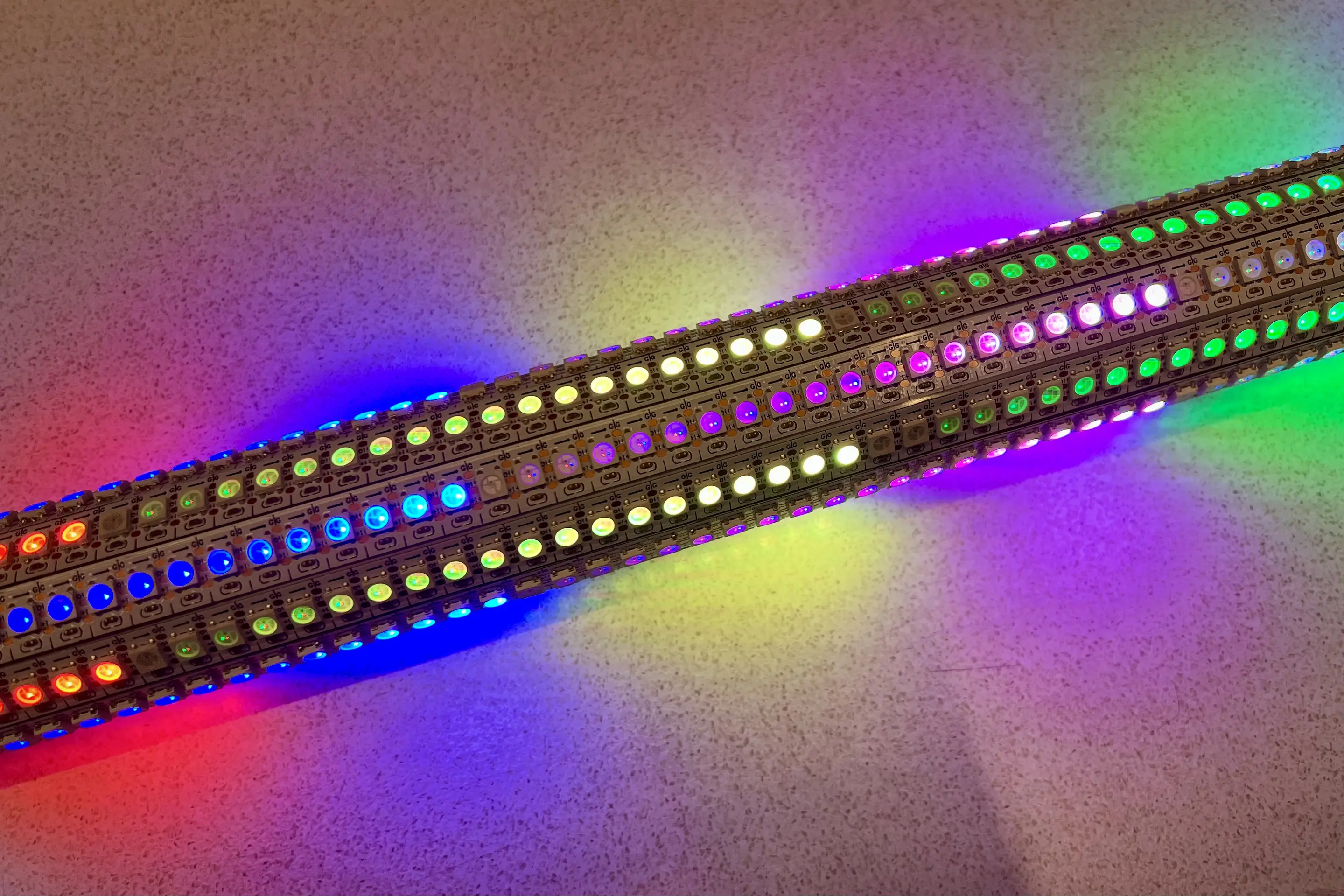

Two bright LED tubes visualize the measured distance, the tolerance range and make every change of state of the functional model immediately visible.

Sensor position

The two brightly orange rings move synchronously with the height-adjustable lower sensors and indicate their position or the measured distance.

The rings of the upper radar sensors, however, remain fixed in their position, as do the sensors themselves.

Radar pulse

The blue rings with glowing tails represent the radar pulses traveling at 300,000 km/s, shown here greatly slowed down.

The signals start at the lower sensor, are reflected at the upper one, and return synchronously at equal distance or with a time offset at different distances.

This illustrates the principle of time-of-flight measurement.

Tolerance range

If a sensor moves, green rings light up to mark the tolerance range. This is the allowable margin in which one sensor may move independently of the other.

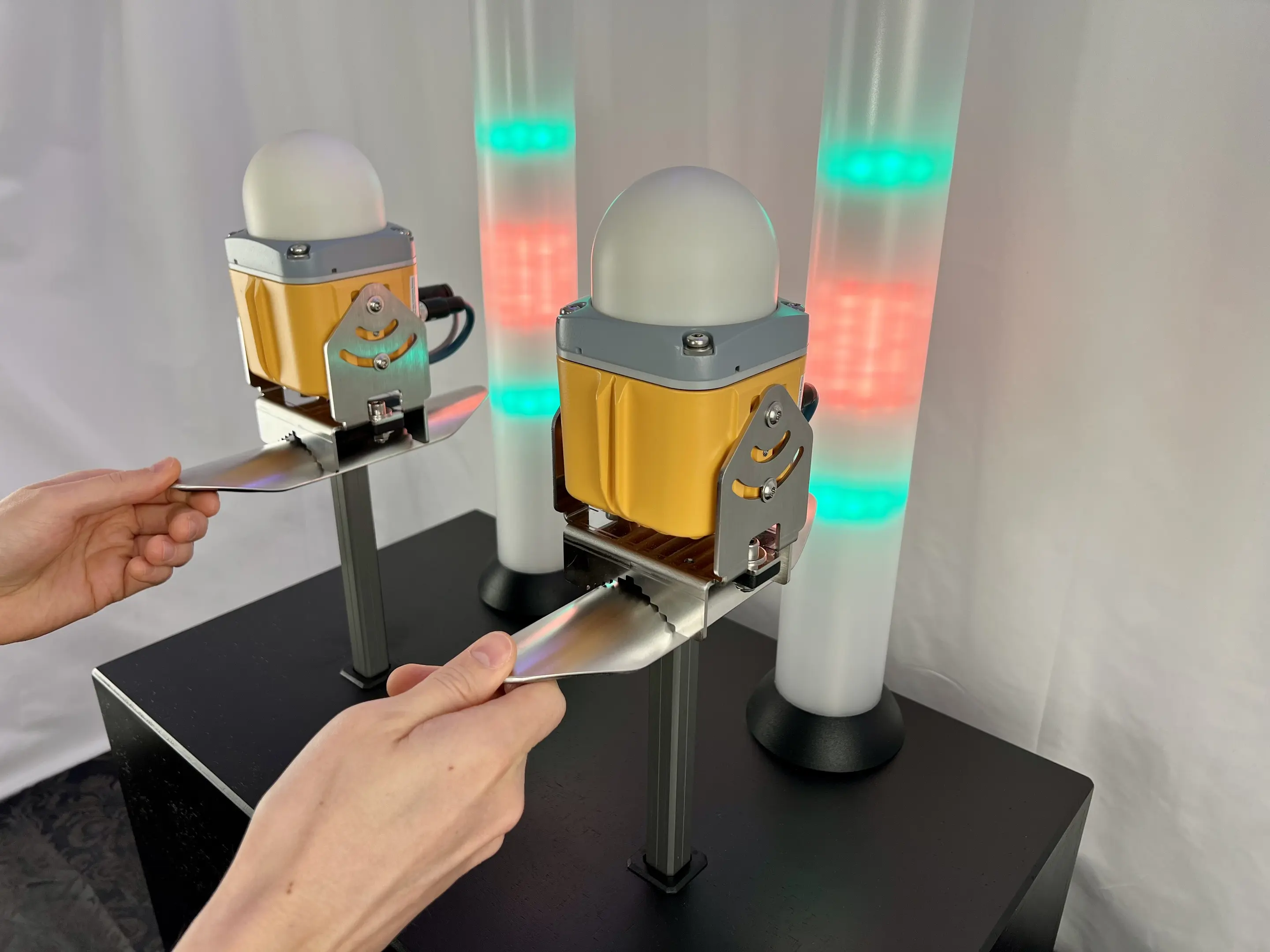

Parallel displacement

If both radar sensors move in parallel in the same direction (here upwards), the tolerance range moves along. Both sensors remain always within the safe zone.

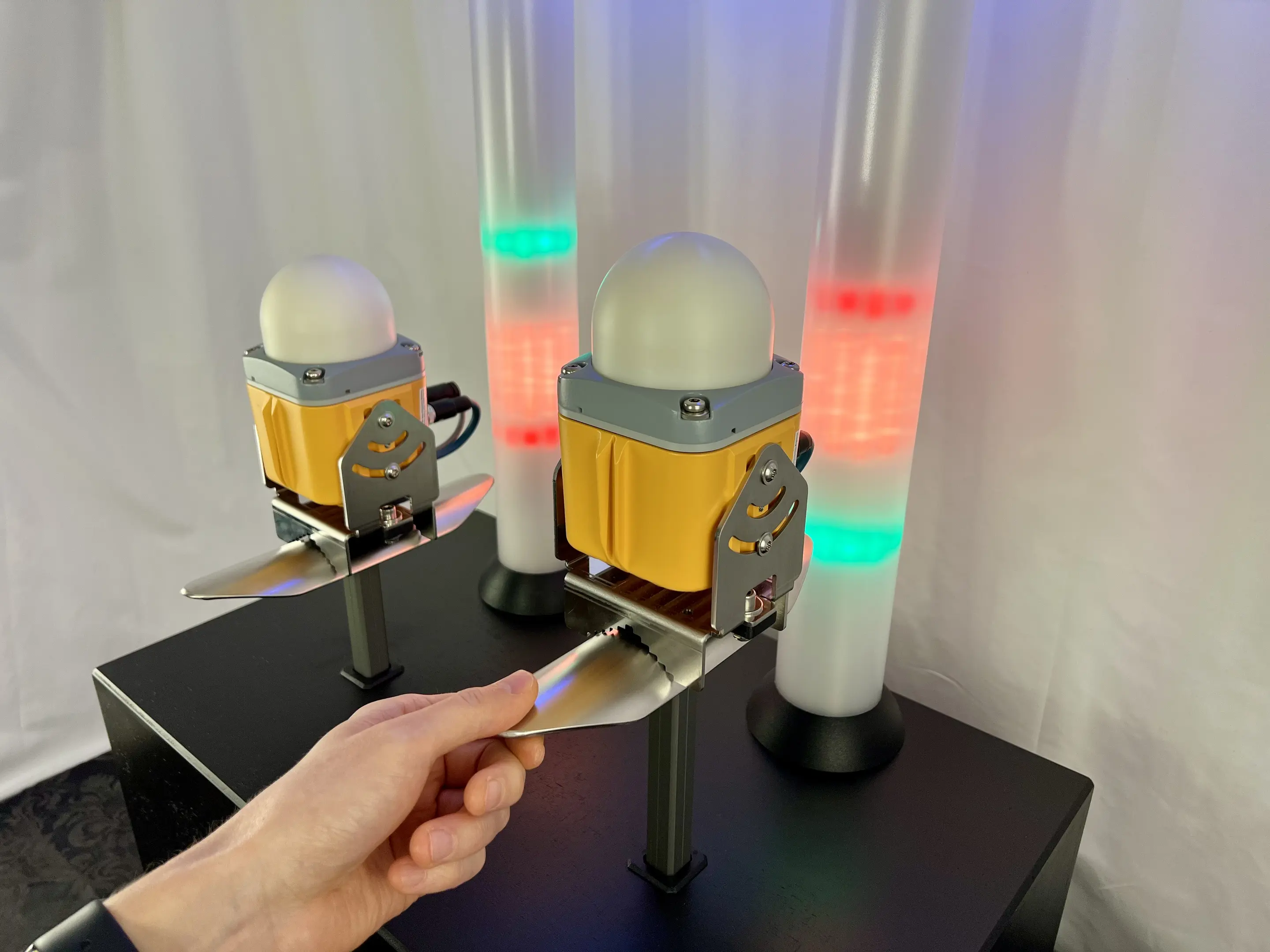

Opposing displacement

If the radar sensors move offset from each other, they produce different measurements and the boundary lines change from green through orange to red.

Alarm on threshold violation

If the difference between the sensors exceeds the tolerance range, the measurement breaches the limit line. An alert is triggered immediately and the LED tubes flash red.

Games & Easter Egg

To lighten the atmosphere at the trade show booth, two interactive games and an Easter egg were programmed into the functional model:

In the first game, inspired by “Beer Pong,” the aim is to throw a virtual ball into a “cup” of markings with a sensor movement-touch sensitivity is required!

In the second game, “Space Egg,” the player controls a hen (sensor marker) and must position it over an egg (color stripe) to hatch it. The player who hatches their chick first (stripe color change from red to green) wins.

The Easter Egg reveals a beautiful rainbow running light that flows like falling drops of color from top to bottom. It is activated when the sensors are moved against each other for several seconds.

Ooh, Aah, Wow! Customer magnets for your trade show booth.

The Glaser engineering office develops and manufactures custom exhibition exhibits. As eye-catchers they attract visitors' attention at your booth with a curious “Ooh”. The benefits of your product become clear and tangible on the demonstration model with an amazed “Aah”. With a final “Wow!” you, your product and your brand remain memorable.

Development, construction, and design of the functional model

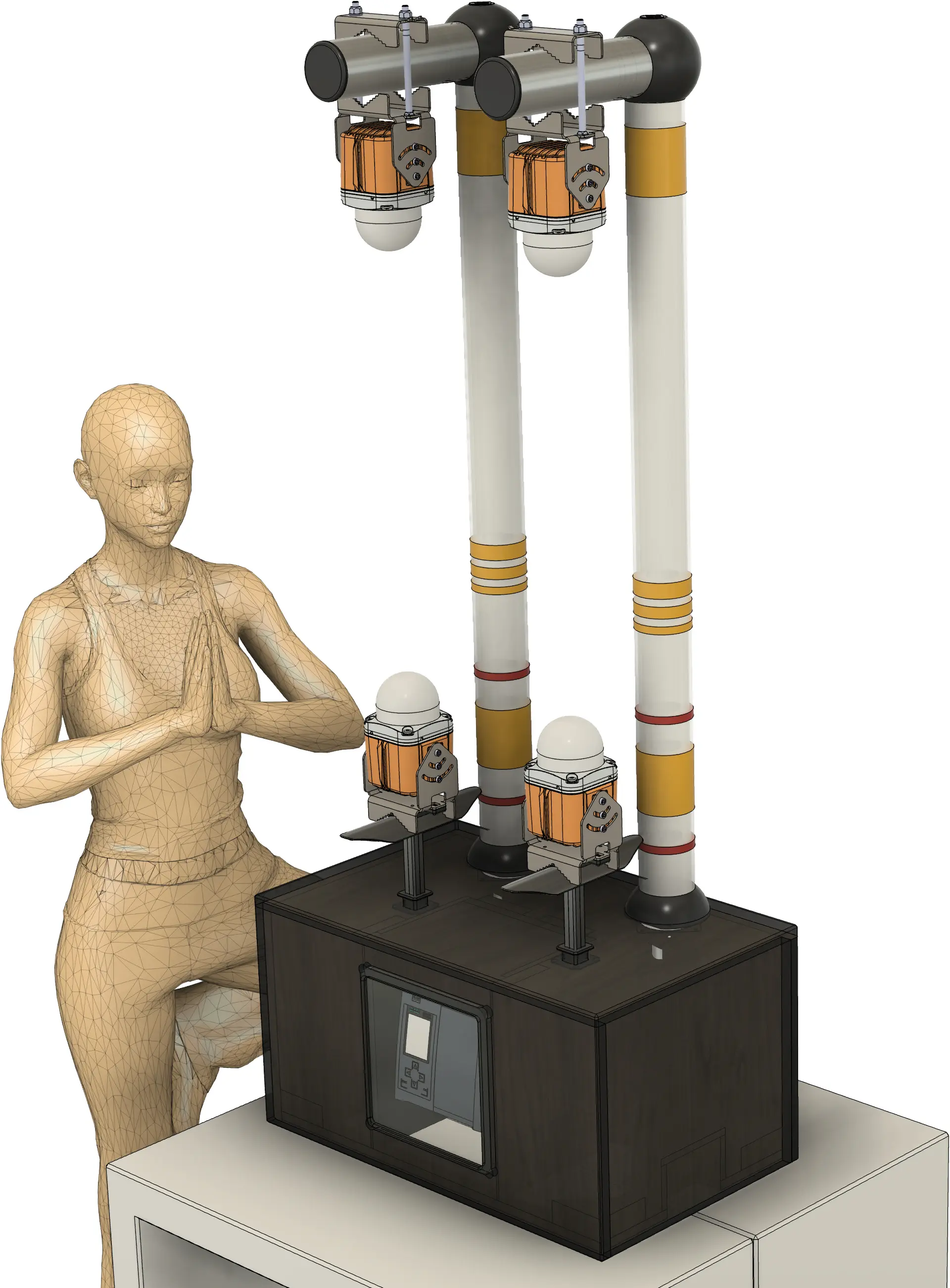

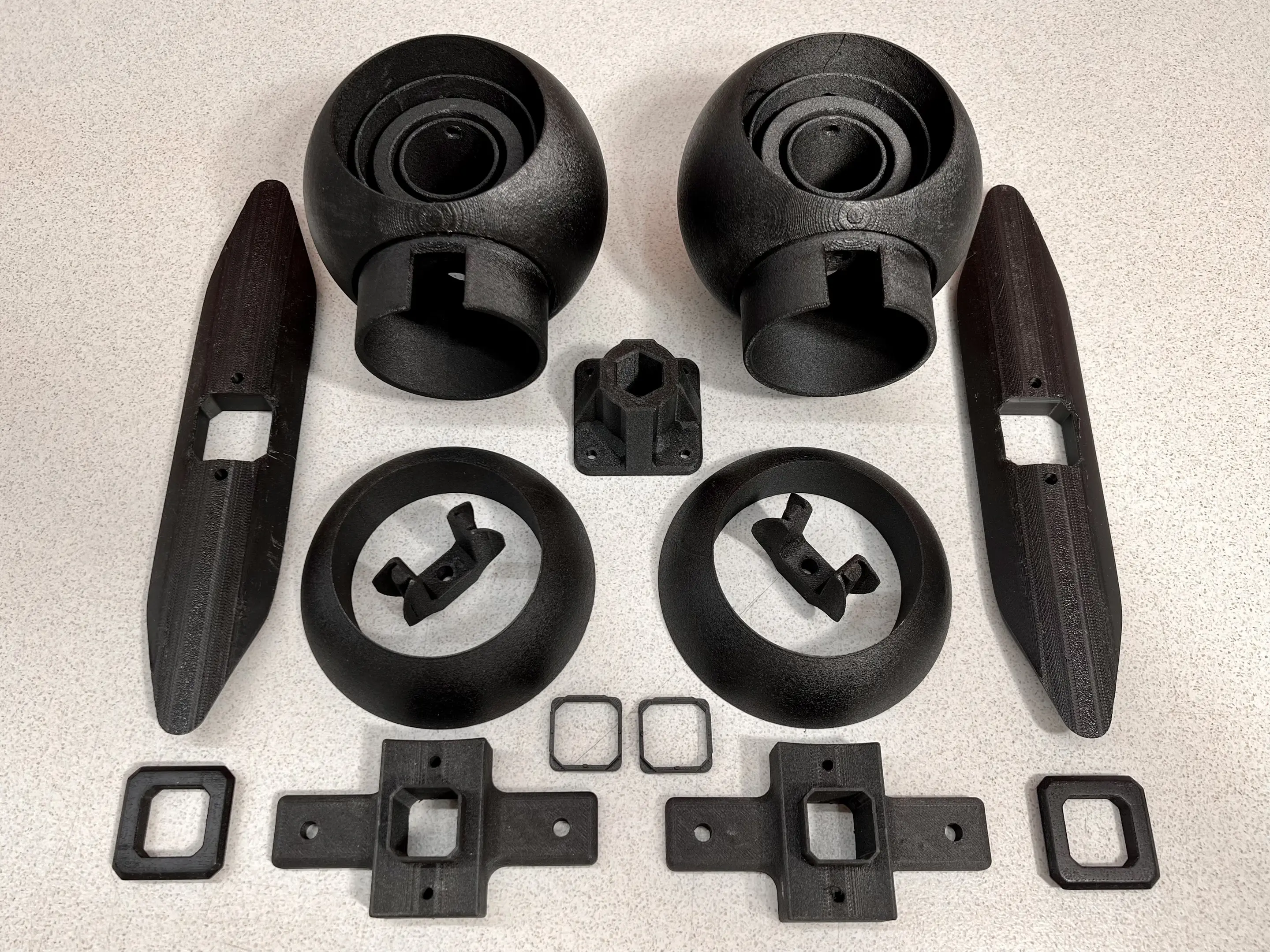

To ensure smooth production of the trade show model, the entire model was designed in detail in 3D.

Two matte-transparent columns integrate perfectly into the clean, white design of the booth and make the upper sensors appear to float. The vivid light effects in the columns visualize the radar signals and draw visitors' attention.

An elegant, black base highlights the two SYMEO radar sensors on a dark surface and makes them stand out optimally through contrast. The lower sensors are supported by ergonomically designed stainless steel tube segments that invite interaction.

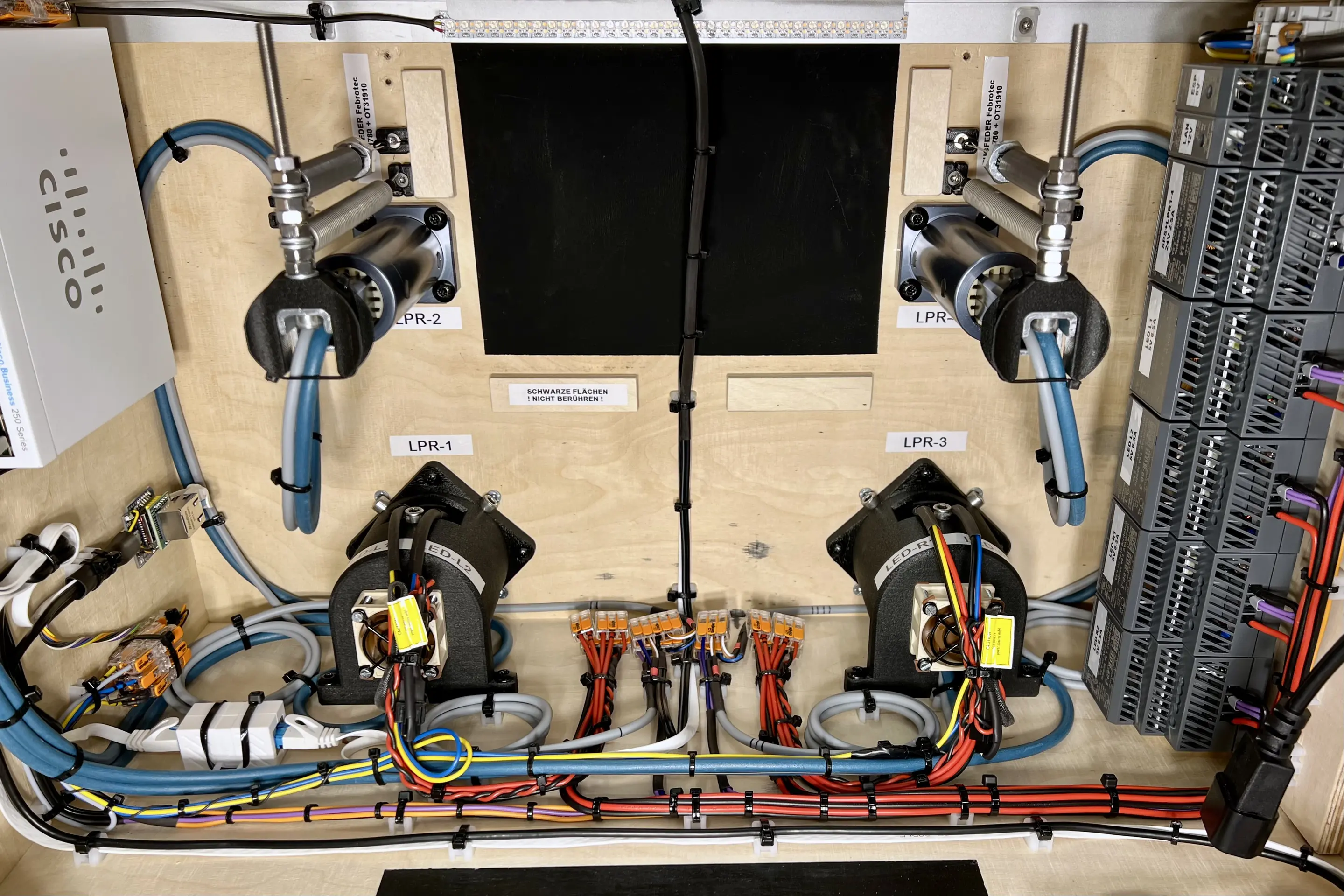

A square viewing window in the base allows a view of the connected Siemens PLC control, establishing the industrial application context.

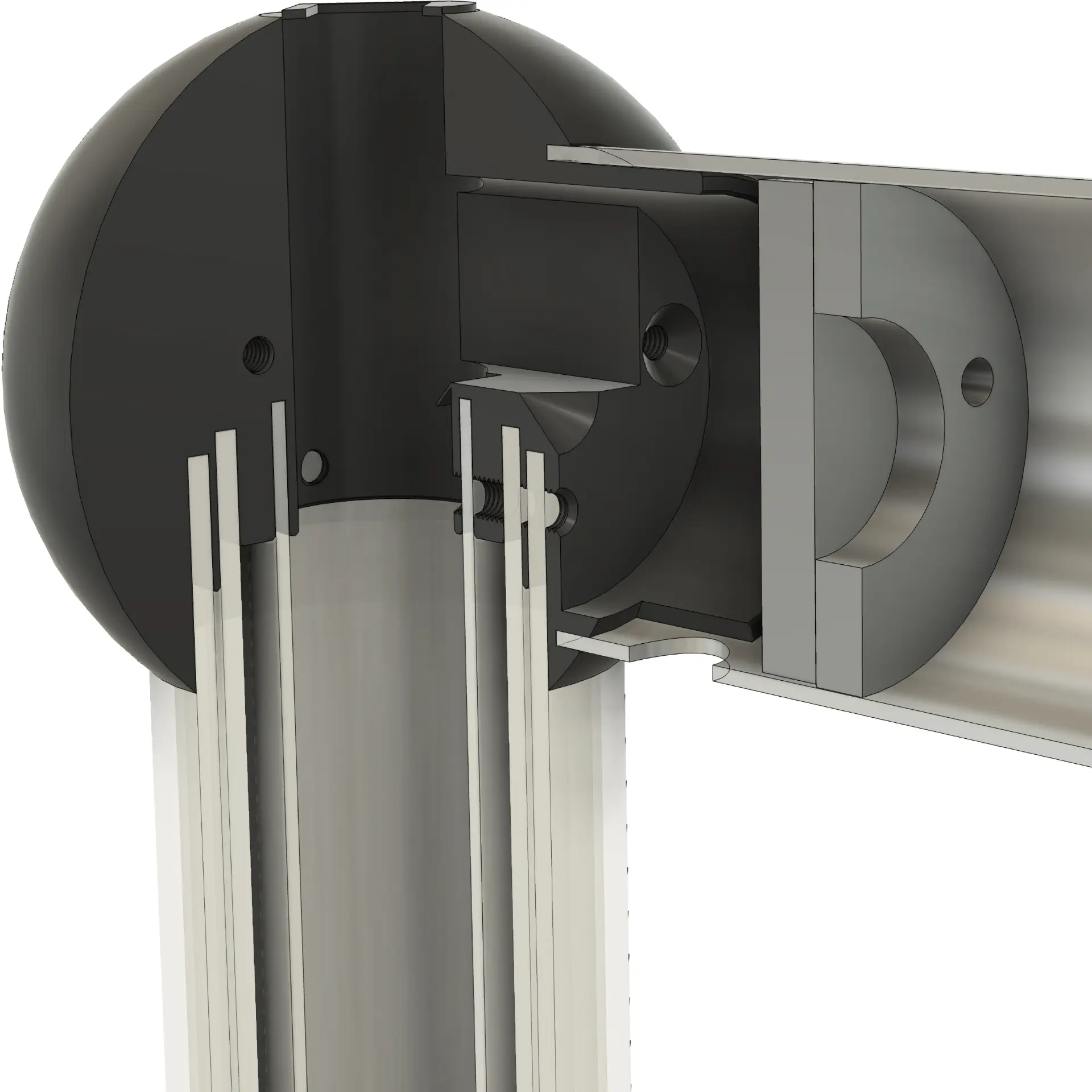

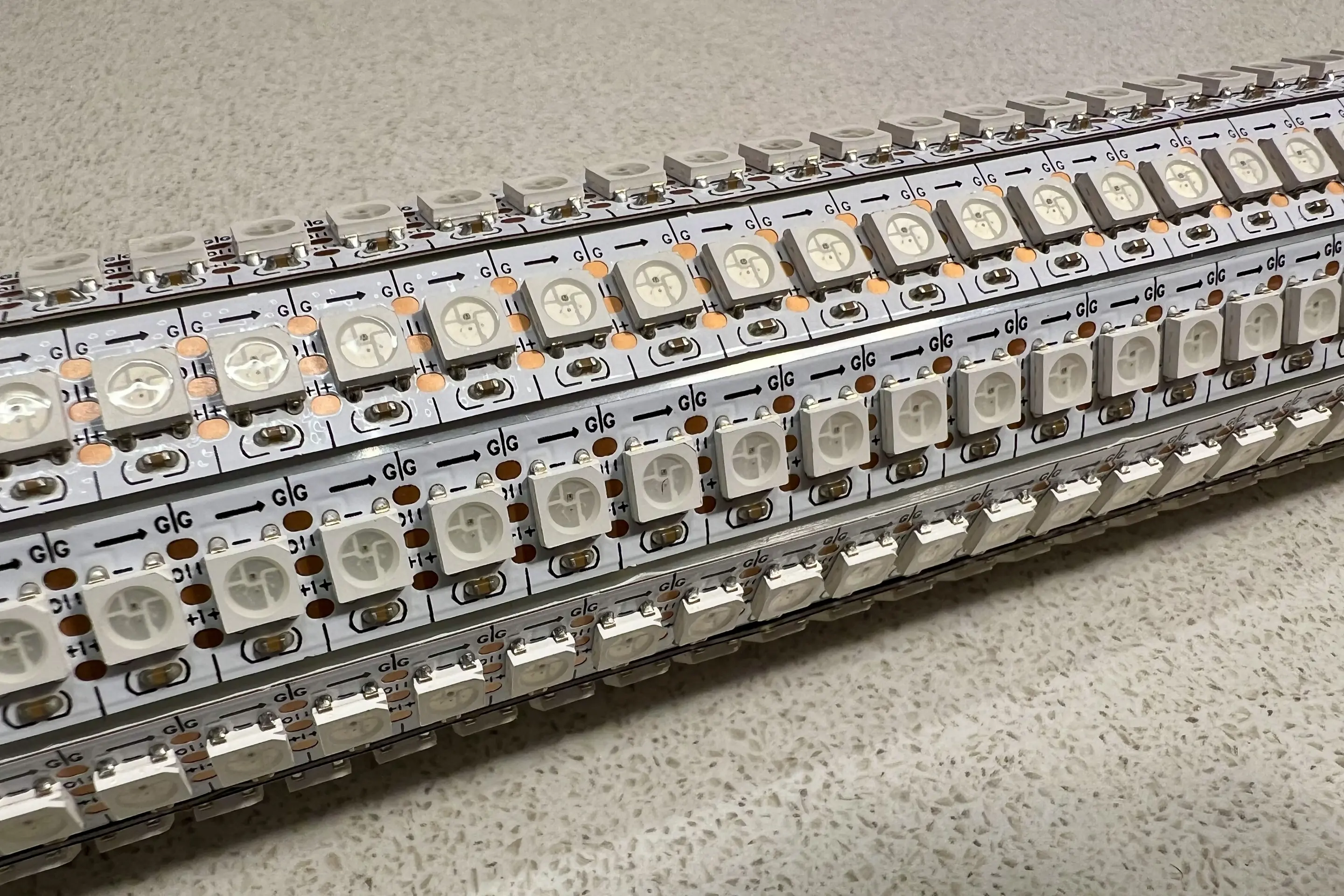

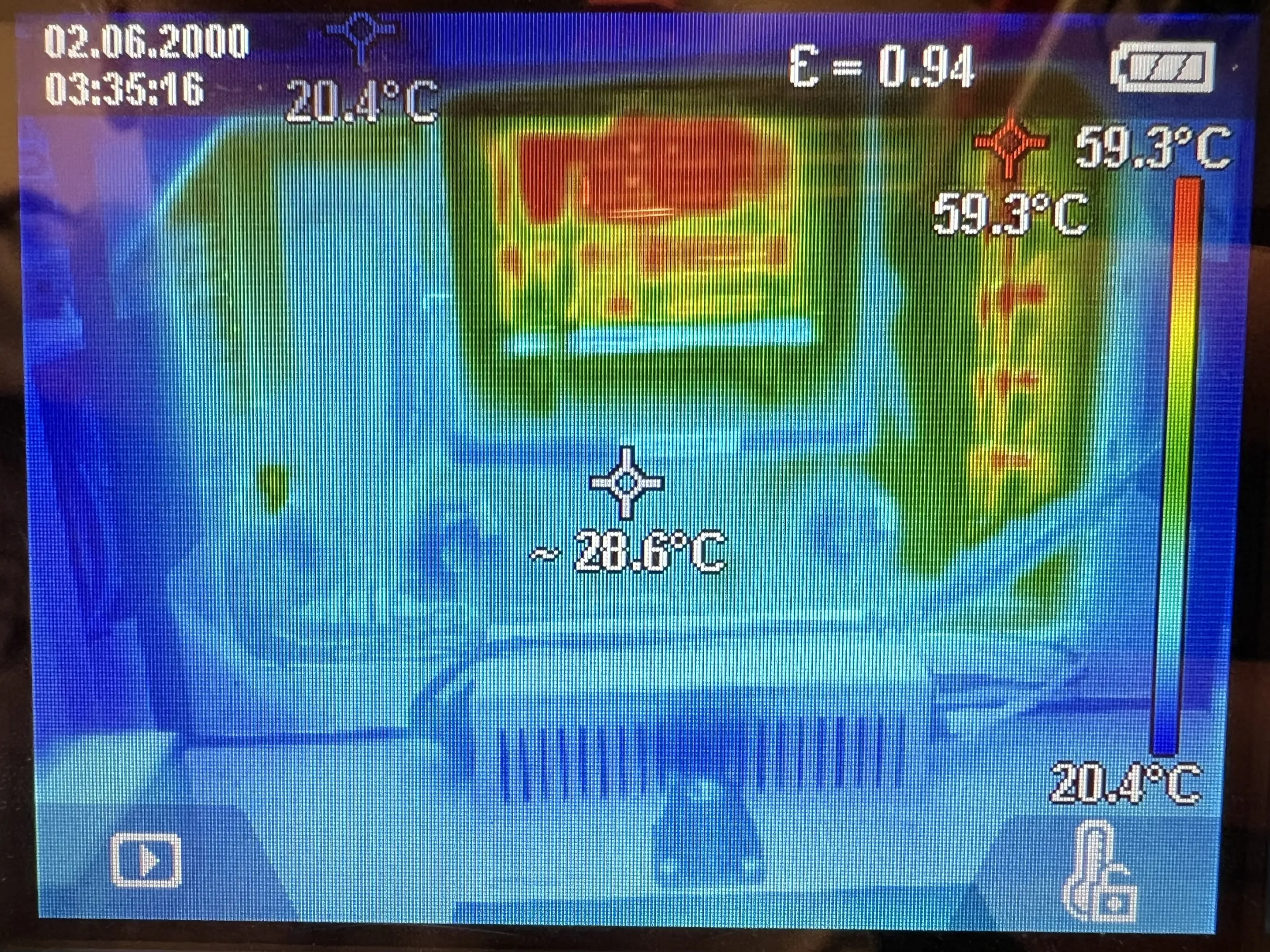

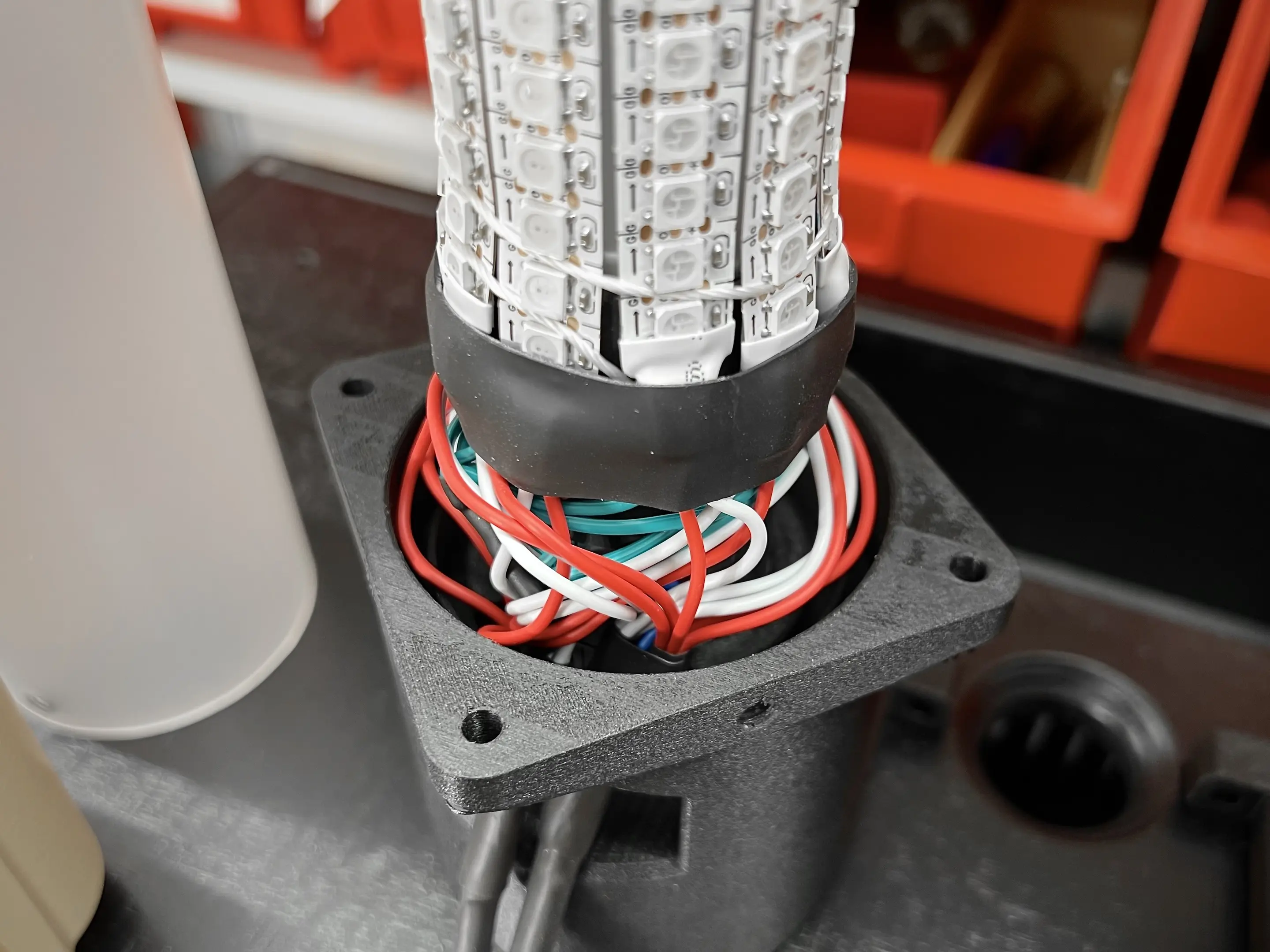

The construction of the LED tube presented a particular challenge: an aluminum tube that simultaneously serves as the carrier for the LEDs, a ventilated heatsink, and a cable conduit gives the column the necessary stability. In addition, two acrylic tubes acting as diffusers to gently scatter the LED light were integrated. With this combination, both functional and aesthetic requirements had to be met.

Software & Electronics & Mechanics

The perfect interplay of microelectronics and custom-made mechanics.

Electronics - High-performance ESP32 microcontroller

Hidden in the base of the functional model is the powerful control electronics that processes the sensor signals and also controls the LED tubes. The centerpiece is an ESP32 dual-core 32-bit microcontroller that is programmed in C++ and produces impressive LED effects at up to 120 FPS. The radar sensors are connected via a CISCO switch over Ethernet.

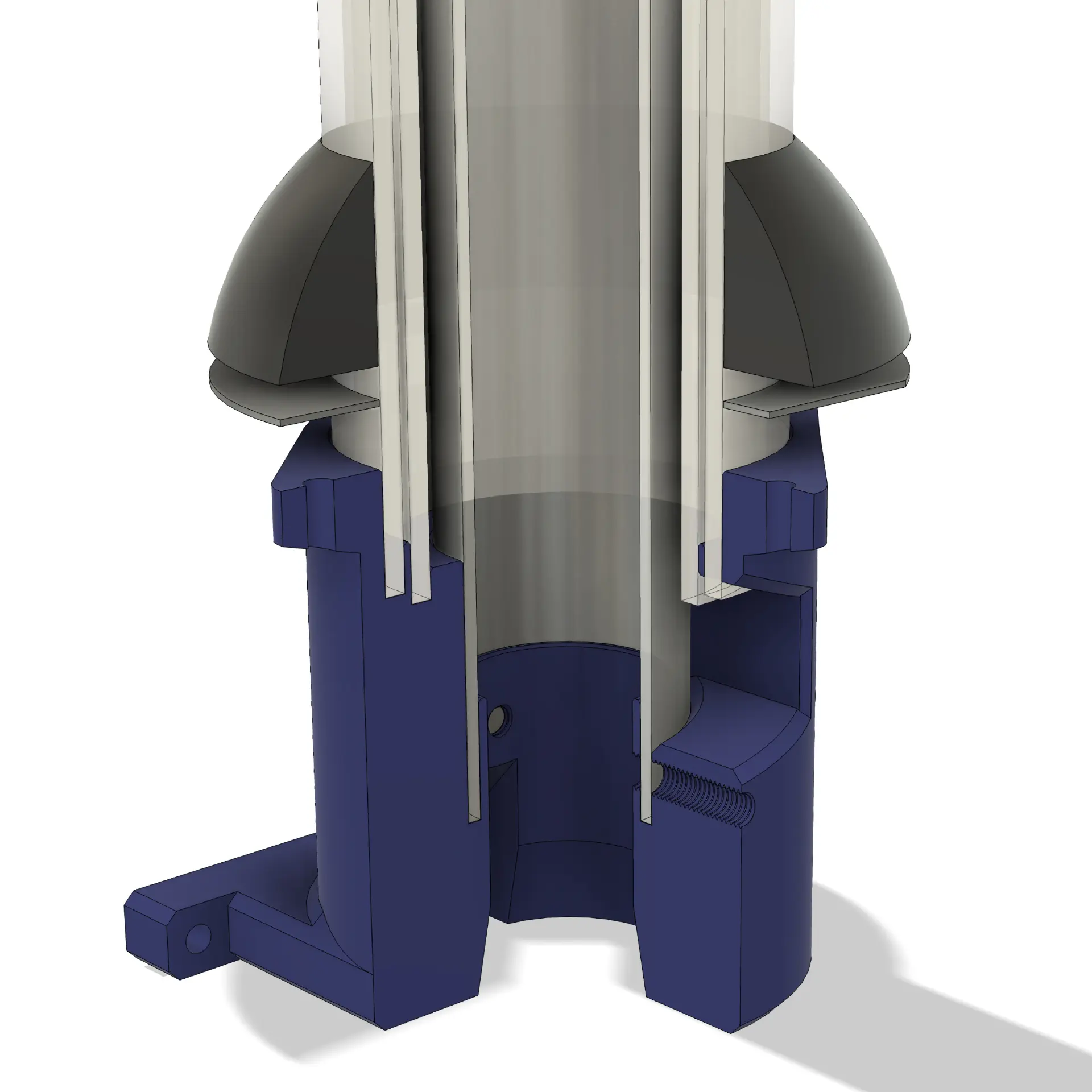

Mechanics - Two-stage suspension for a defined center position

An Igus plain bearing enables smooth movement of the sensor in the Z direction and reliably prevents rotation about its own axis.

The well-thought-out combination of two tension springs keeps the sensor precisely in the center position. One spring carries nearly the entire self-weight of the sensor, while the second spring catches the remaining weight force only beyond the center position due to its preloading. In this way, an exactly defined central rest position is achieved despite bearing friction and manufacturing tolerances.

Electronics - LED tube with integrated cooling system

A total of 3,000 LEDs of the type WS2812 ECO were installed in two acrylic tubes of the functional model for displaying measurements and light effects. The energy-efficient LEDs are wired in series in a daisy chain, which makes it possible to control all RGB LEDs grouped together with only a few data lines from a single ESP32 microcontroller.

A cooling system with high-quality Noctua PC fans generates a constant airflow inside the tubes and the base. This reliably cools the power supplies and LEDs, ensuring long-lasting performance.

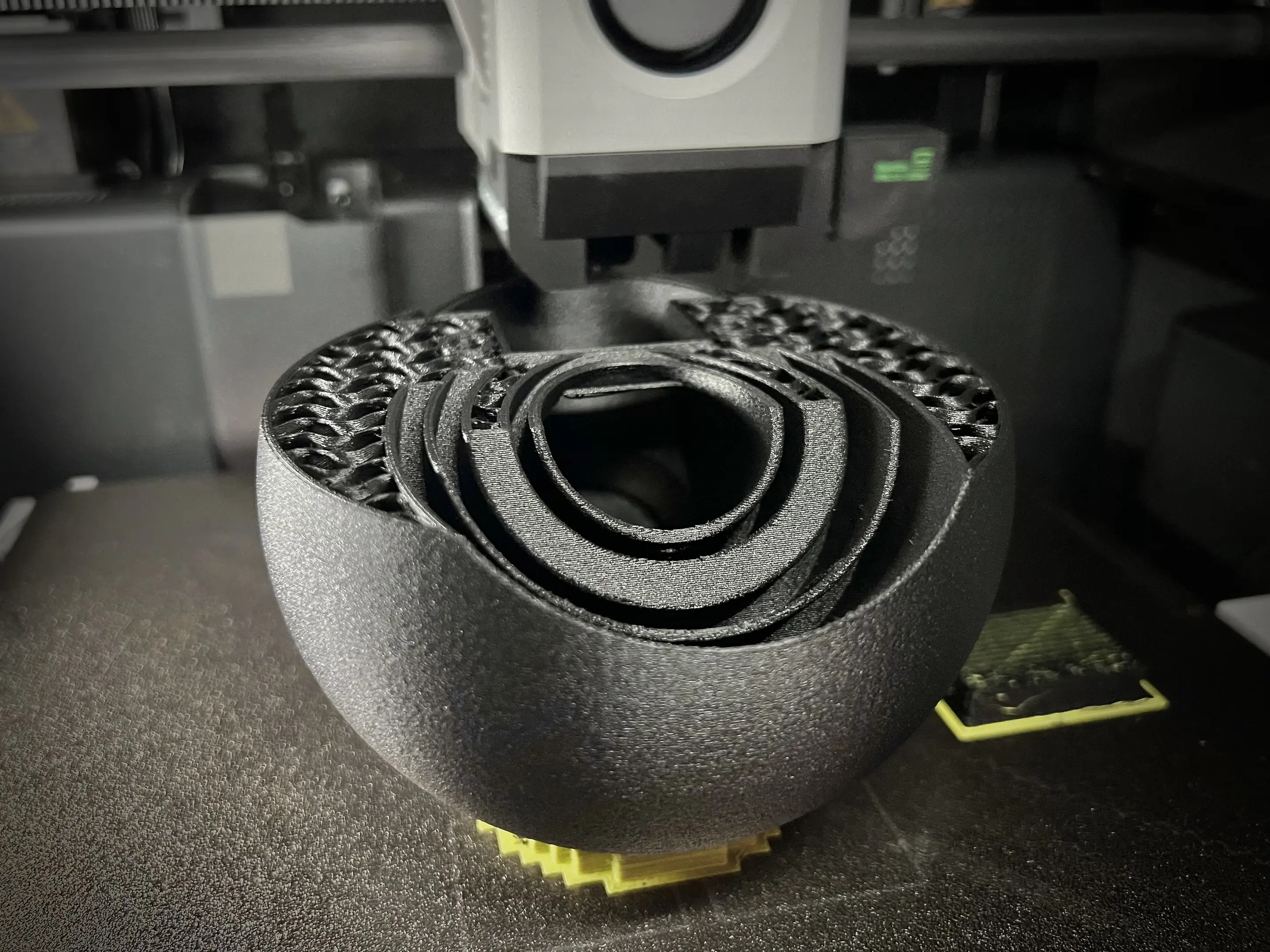

Manufacturing - Professional 3D printing

All components with complex geometries were manufactured on a Bambu Lab X1E 3D printer. The carbon-fiber-reinforced filament used, PAHT-CF (high-temperature resistant nylon), is particularly durable and withstands high loads.

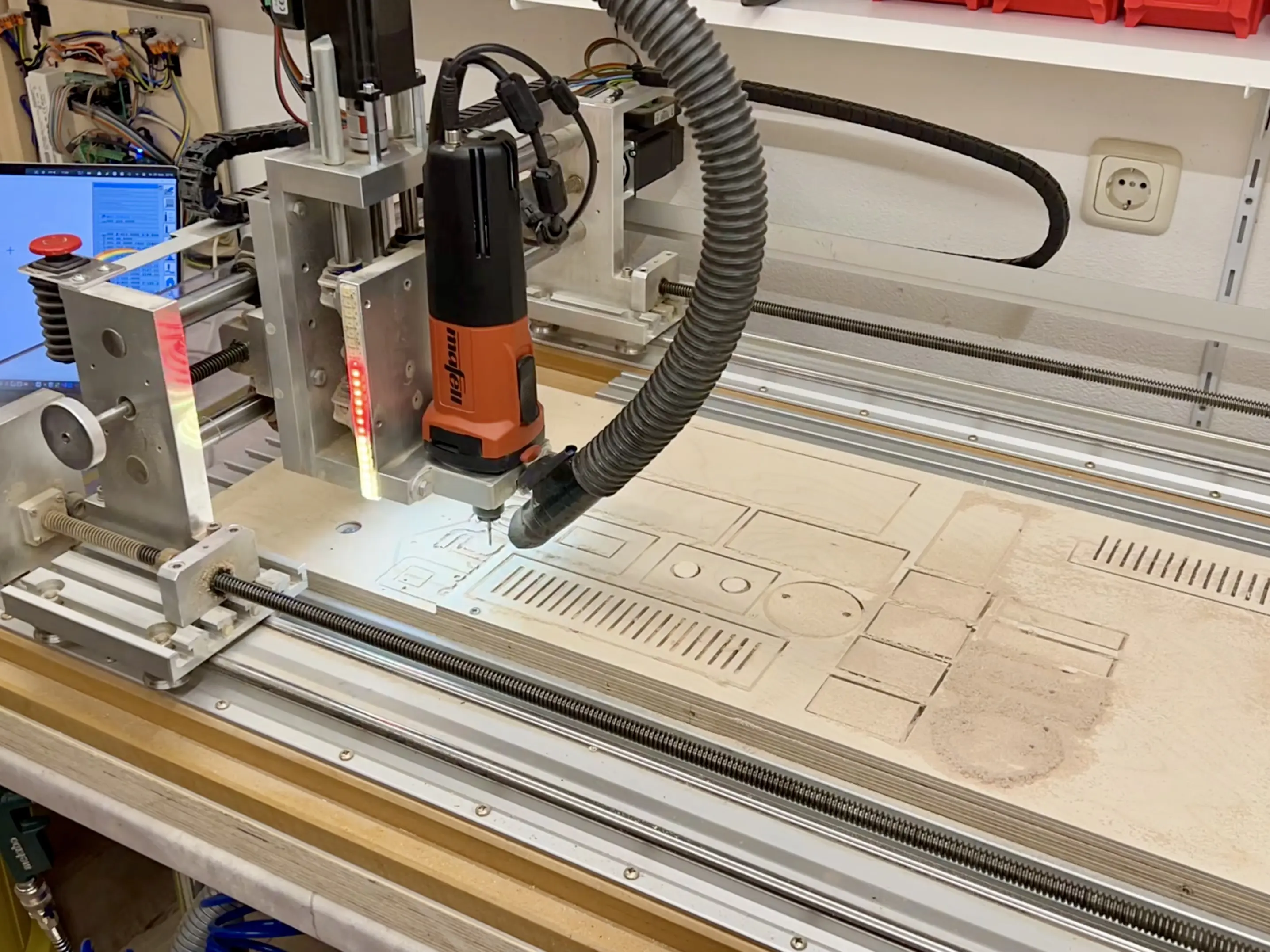

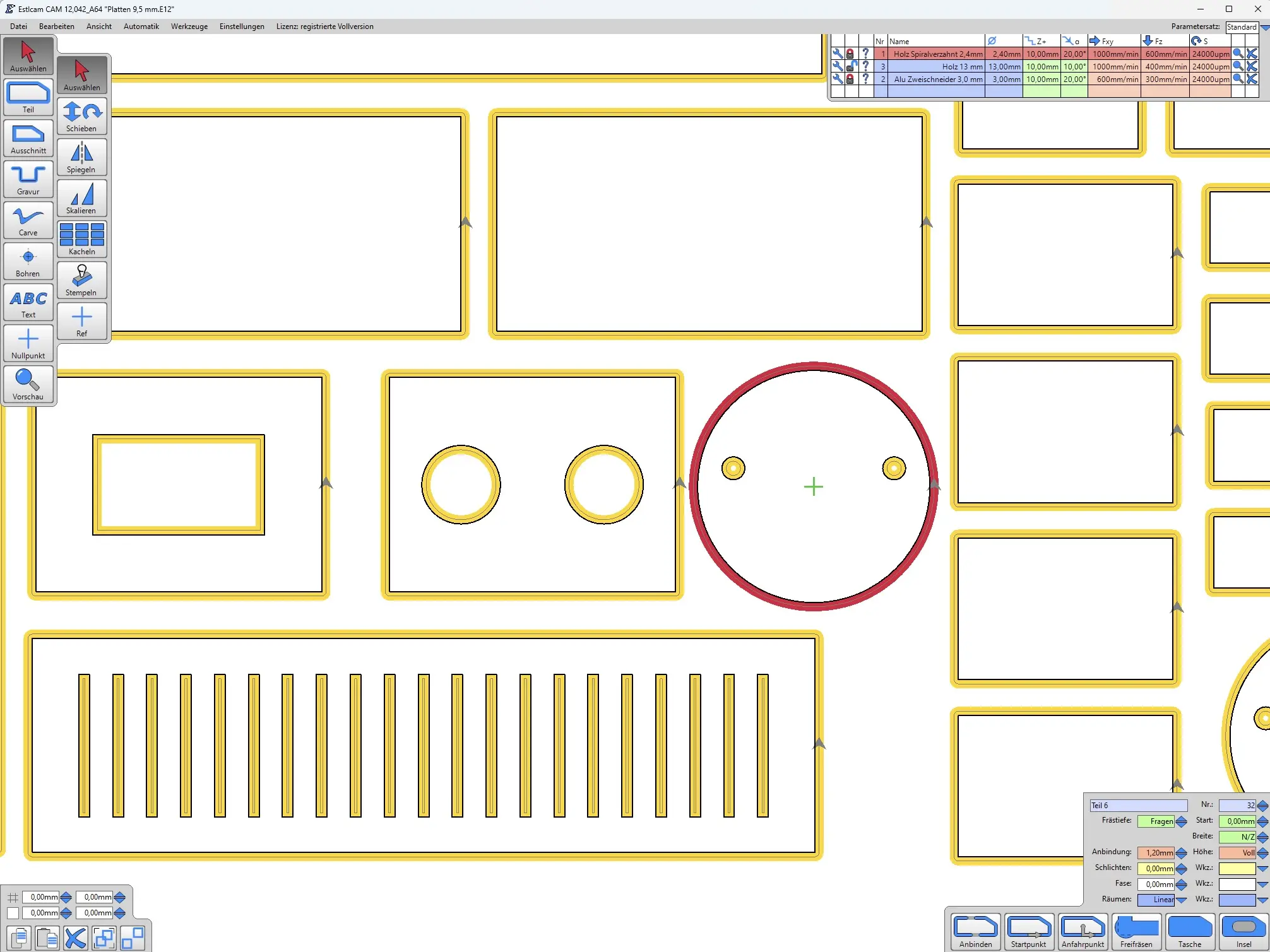

Manufacturing - CNC milling for highest precision

To ensure maximum fit accuracy and minimize post-processing effort, all required wooden parts of the functional model were CNC-manufactured and could be assembled directly with precise fit.

Shipping - Custom Transport Case

A transport box specially designed for the functional model ensures quick setup and teardown and provides optimal protection during transport of the valuable trade show object.

Behind the Scenes

Behind the scenes, work was carried out with passion and creativity. The development and construction of the functional model were a perfect combination of software, electronics and hardware. From precise CAD design through manufacturing by CNC and 3D printing to programming in C++, I was able to contribute everything that makes my engineer's heart beat faster. Especially the programming of the LED effects left a lot of room for creativity and made the project a real highlight.

Already during manufacturing and especially after completion, the functional model provided an excellent opportunity to fully pursue my passion for photography and videography. The individual steps of the production process as well as the impressive lighting effects made the project a fascinating subject for the camera.

Quick Guide

... for the SYMEO team at the trade show booth.

Radar Demonstrator II - Quick Guide

Functional Model Power On

① Plug in ② Switch on ③ Wait 3 min for sensors

Show boundaries

Show ➔ Move a sensor (automatic hide after 5 s)

Smaller ➔ Hold both sensors upwards for 5 s

Larger ➔ Hold both sensors upwards for 5 s (or 30 s inactivity)

Game “Beer Pong”

Throw the ball by hand (sensor) into the cup (two blue boundary lines).

The player who hits the cup first wins.

Start ➔ Hold the left sensor upwards for 7 s

End ➔ Hold both sensors downwards for 5 s (or 30 s inactivity)

Game “Space Egg”

Place the hen (sensor marker) on the egg (color stripe) to “hatch” it.

The player whose chick hatches first (red ➔ green) wins.

Start ➔ Hold the right sensor upwards for 7 s

End ➔ Hold both sensors downwards for 5 s (or 30 s inactivity)

Bonus “Easter Egg”

A colorful rainbow pattern that flows from top to bottom.

Each time the Easter Egg ends, it switches between color themes.

Start ➔ Move both sensors rapidly up and down in opposite directions

End ➔ Move one sensor

by ingenieur-glaser.de ∙ +491701079241

THANK YOU!

Many thanks to the trade fair team of Symeo GmbH from Munich for the trusting and appreciative collaboration. Especially the friendly and warm personal contact and the creative freedom granted during implementation made this project a thoroughly enriching experience. A valuable collaboration that was positive in every respect.

Thomas Hörl

VP Industry Business Development

"What we particularly appreciate is the perfect adherence to time and cost. The high-quality manufacturing with the appropriate finish. The comprehensive and farsighted planning as an overall project. There is only one reason not to recommend the Glaser engineering firm: because then he would eventually have no time left for our new projects!"

Presentation of the functional model at the SPS trade fair in Nuremberg

At the SPS trade fair in Nuremberg, the functional model attracts attention. With fascinating LED light effects and interactive games, it invites trade fair visitors to explore the world of radar technology in a playful way.