Exhibit

Hygienic Seal Demonstrator

for hygienic seals by Freudenberg

Exhibition stand construction for the drinktec trade fair in Munich

When hygiene convinces visually.

The exhibit makes at a glance visible how particles accumulate in dead spaces of a standard seal, while the hygienic seal from Freudenberg remains completely residue-free. In the acrylic column filled with water it becomes visible how important the right seal design for hygiene and process safety is.

Exhibit for hygienic sealing with water & UV light - drinktec Freudenberg - exhibition stand construction

✨ Fascination in the water flow. The Hygienic Seal Demonstrator shows at a glance what matters for hygienic seals. While particles accumulate in the dead spaces of a standard seal, the Freudenberg hygienic seal remains completely residue-free. In the acrylic column filled with water, under UV light it becomes visible how important the correct seal design is for hygiene and process safety.

https://ingenieur-glaser.de/hygienic-seal-demonstrator/ – Behind the scenes

#Drinktec #Freudenberg #TradeFair #ExhibitionStand #Exhibit #ModelExhibit #FunctionalModel #Booth

🧲 Ooh, Aah, Wow! - Customer magnets for your exhibition stand.

The engineering firm Glaser develops and manufactures custom exhibits. As eye-catchers they attract visitors' attention at your booth with a curious “Ooh”. The advantages of your product become clear and tangible on the demonstration model with an astonished “Aah”. With a final “Wow!” you, your product and your brand will stay in people's minds.

https://ingenieur-glaser.de/messebau/ – Trade show exhibits

💡️ Development & Manufacturing – Engineering office Glaser

https://ingenieur-glaser.de/ – Electronics・Software・Hardware

🔔 Don’t miss any developments. Subscribe now!

https://ingenieur-glaser.de/Instagram/ – Instagram

https://ingenieur-glaser.de/Facebook/ – Facebook

https://ingenieur-glaser.de/YouTube/ – YouTube

https://ingenieur-glaser.de/LinkedIn/ – LinkedIn

https://ingenieur-glaser.de/TikTok/ – TikTok

https://ingenieur-glaser.de/Xing/ – Xing

🥇 How visions became successes.

https://ingenieur-glaser.de/Projekte/ – References

📞 Has the spark ignited?

https://ingenieur-glaser.de/Kontakt/ – Contact

#Drinktec #Freudenberg #TradeFair #ExhibitionStand #Exhibit #ModelExhibit #FunctionalModel #Booth

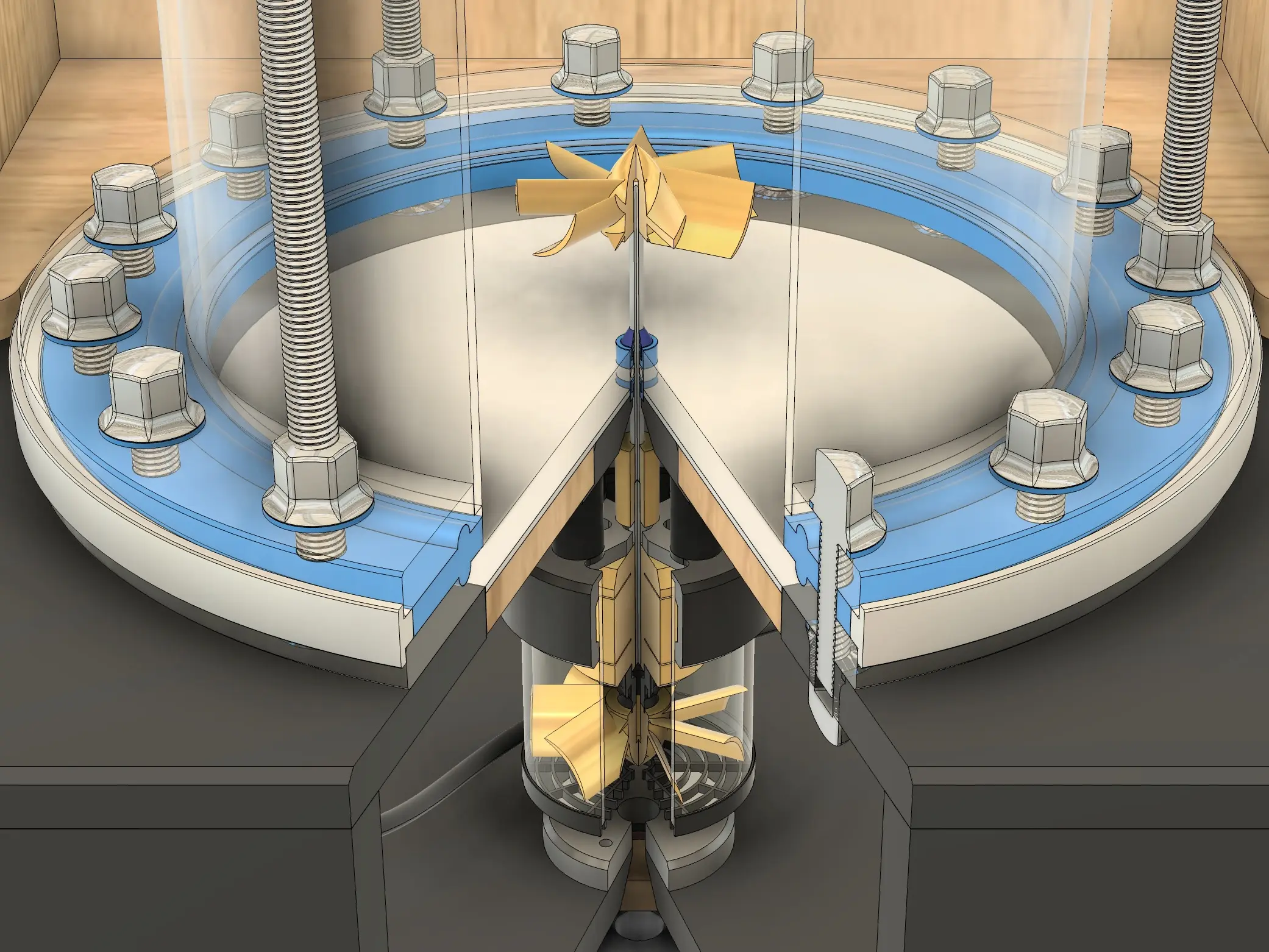

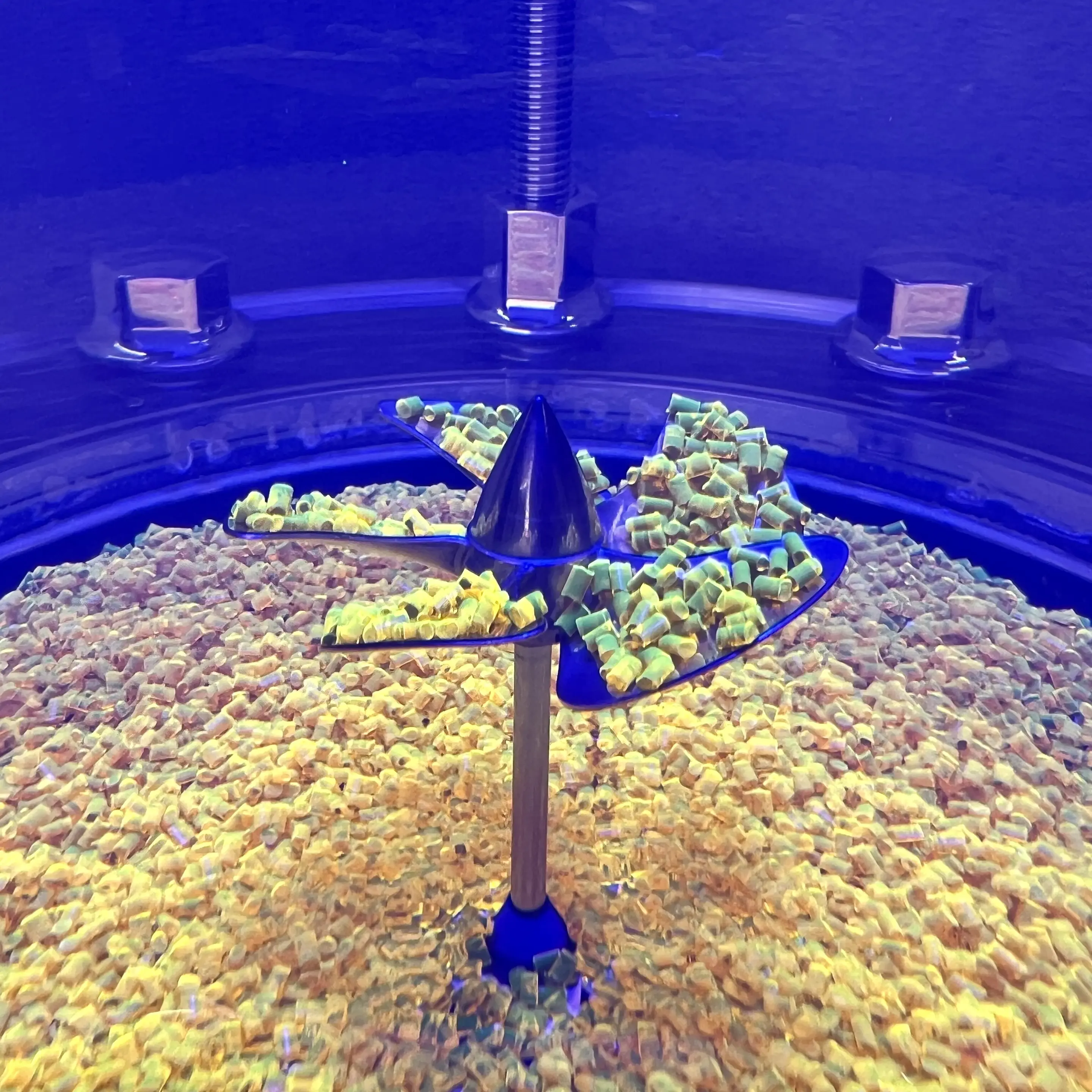

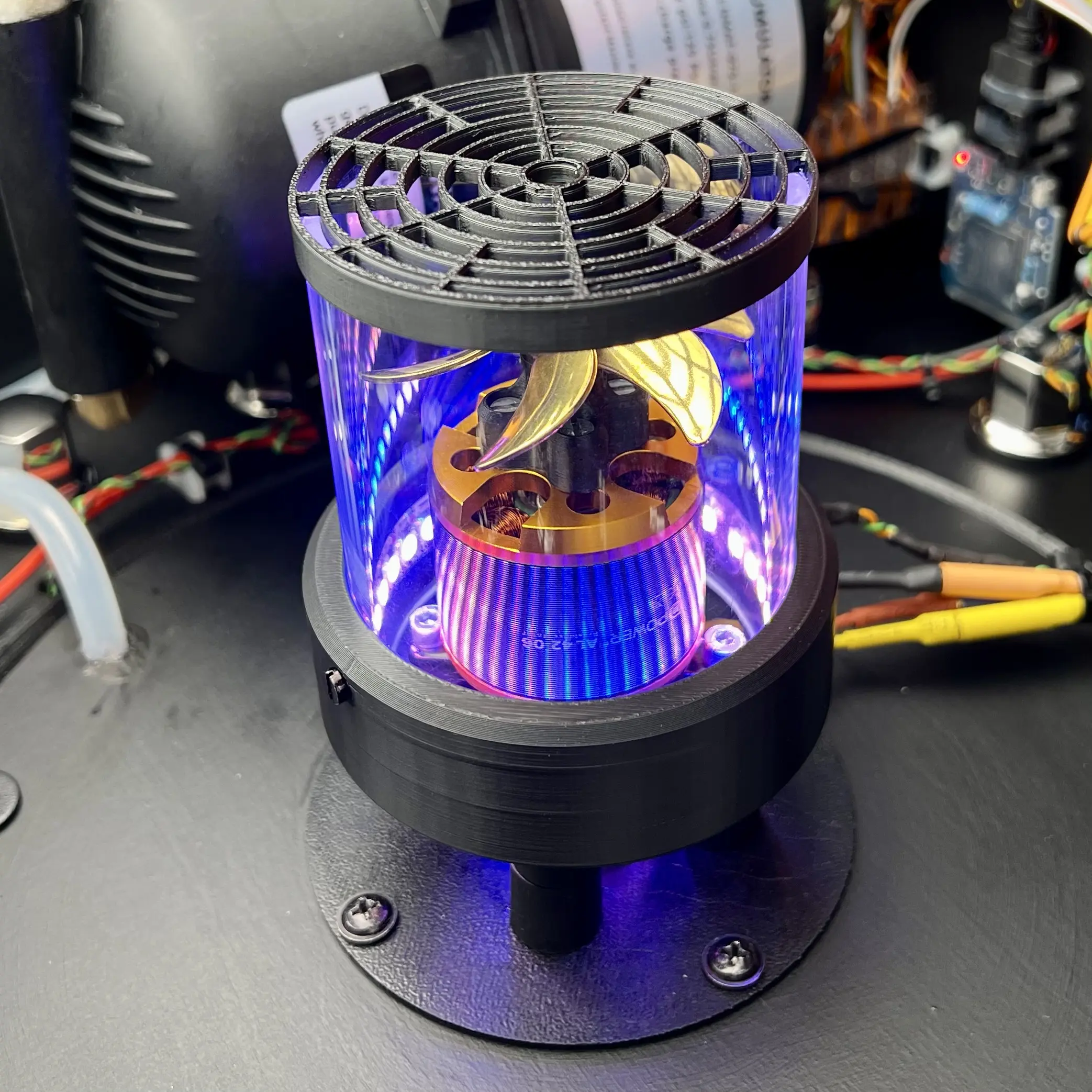

Operating principle of the exhibit

A hydro-impeller, whose motor is built into the base, stirs up fluorescent granulate in the water. The granulate glowing under UV light settles when sinking on the overhanging standard seal, while the hygienic seal remains residue-free.

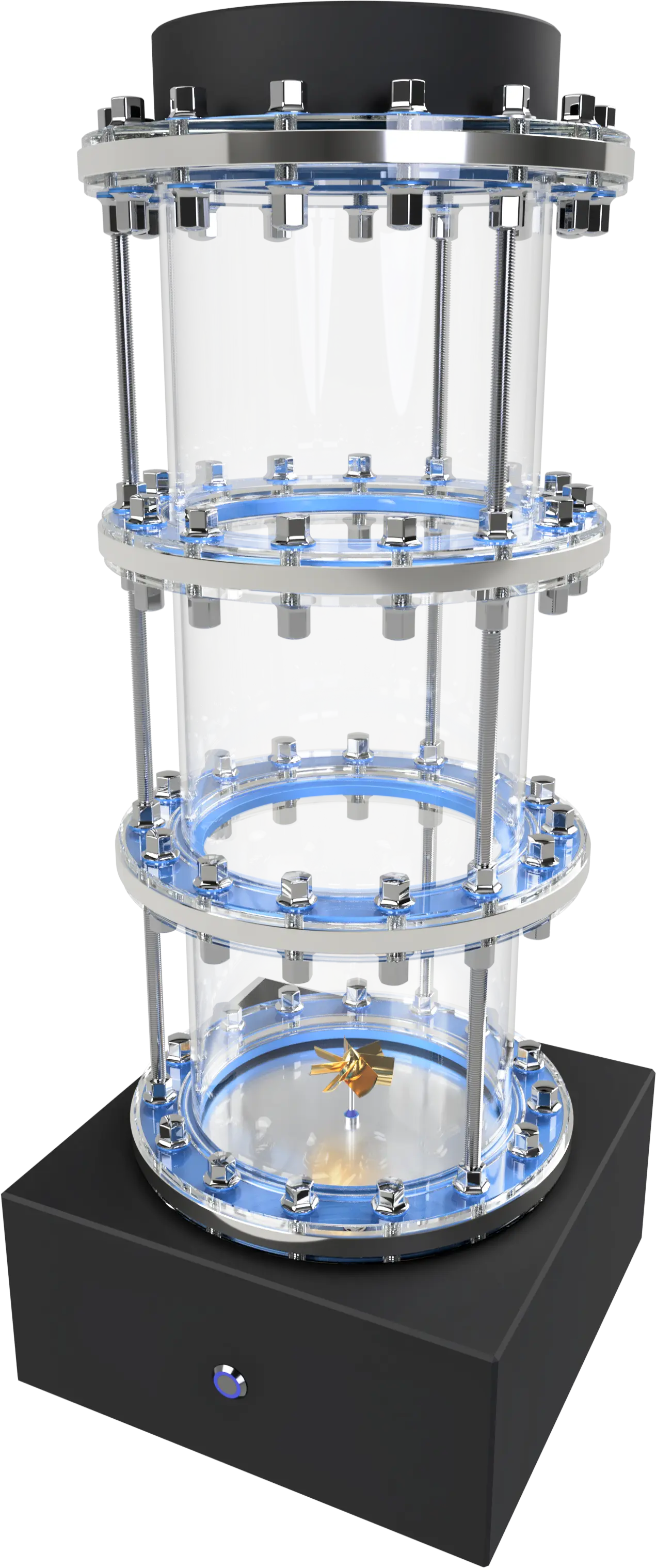

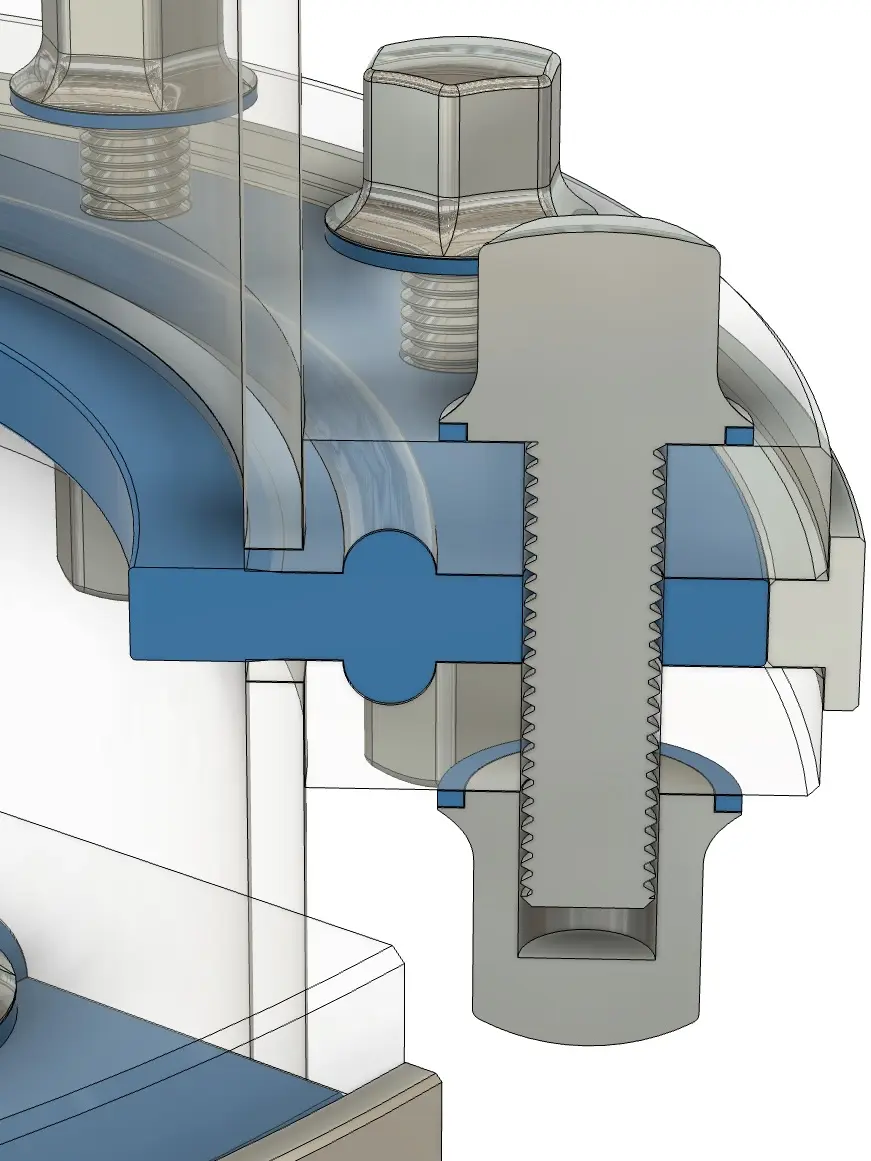

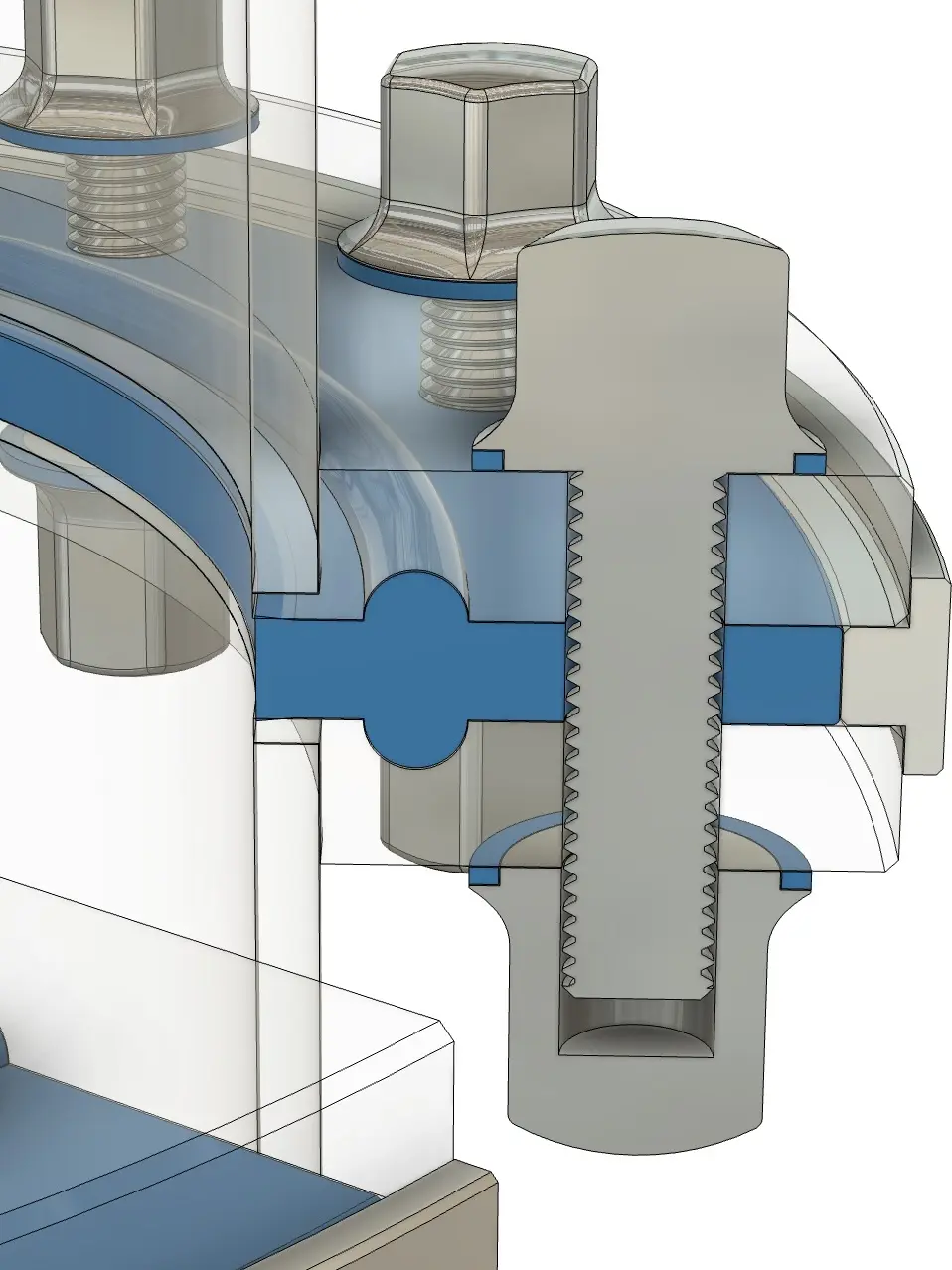

Virtual 3D model

Already in the concept phase the exhibit model was fully constructed in 3D, to optimize proportions, function and design early on.

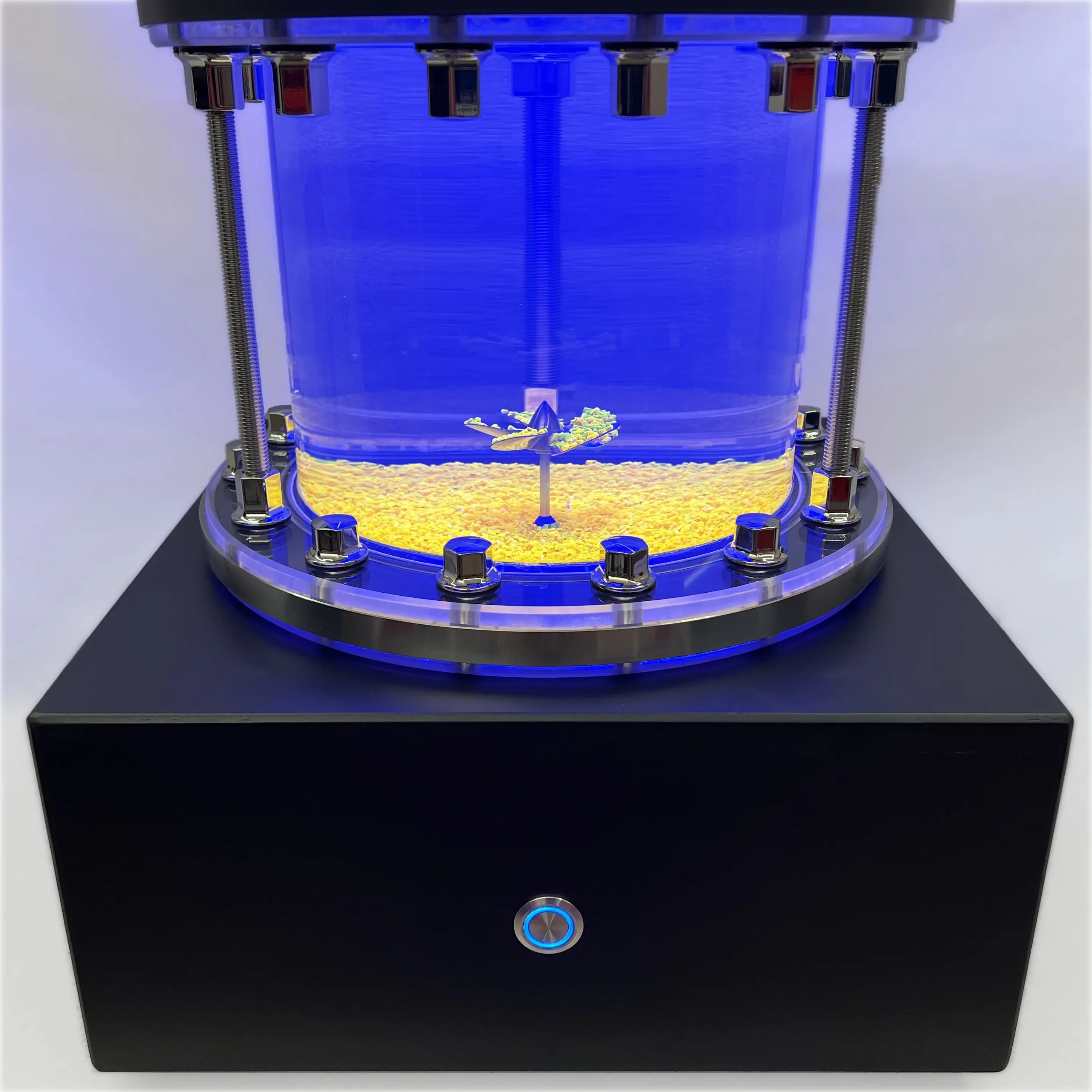

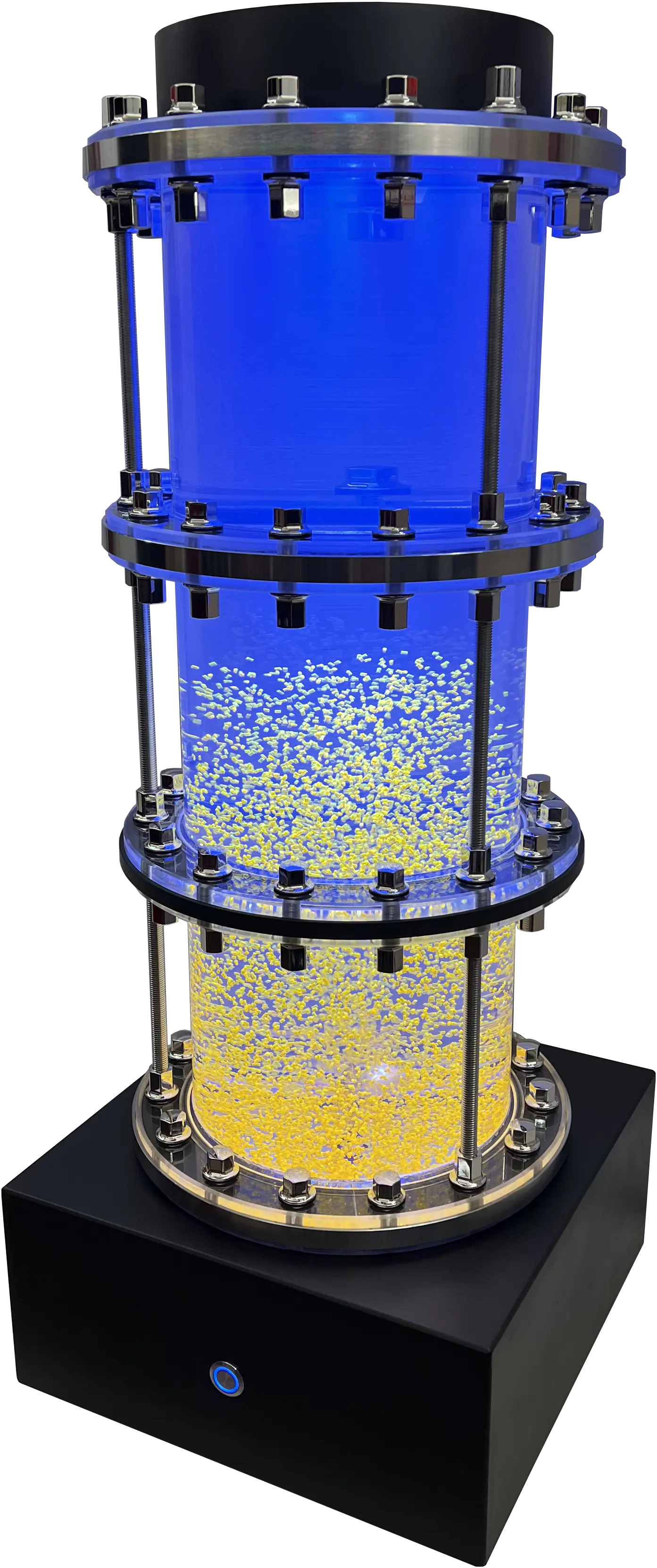

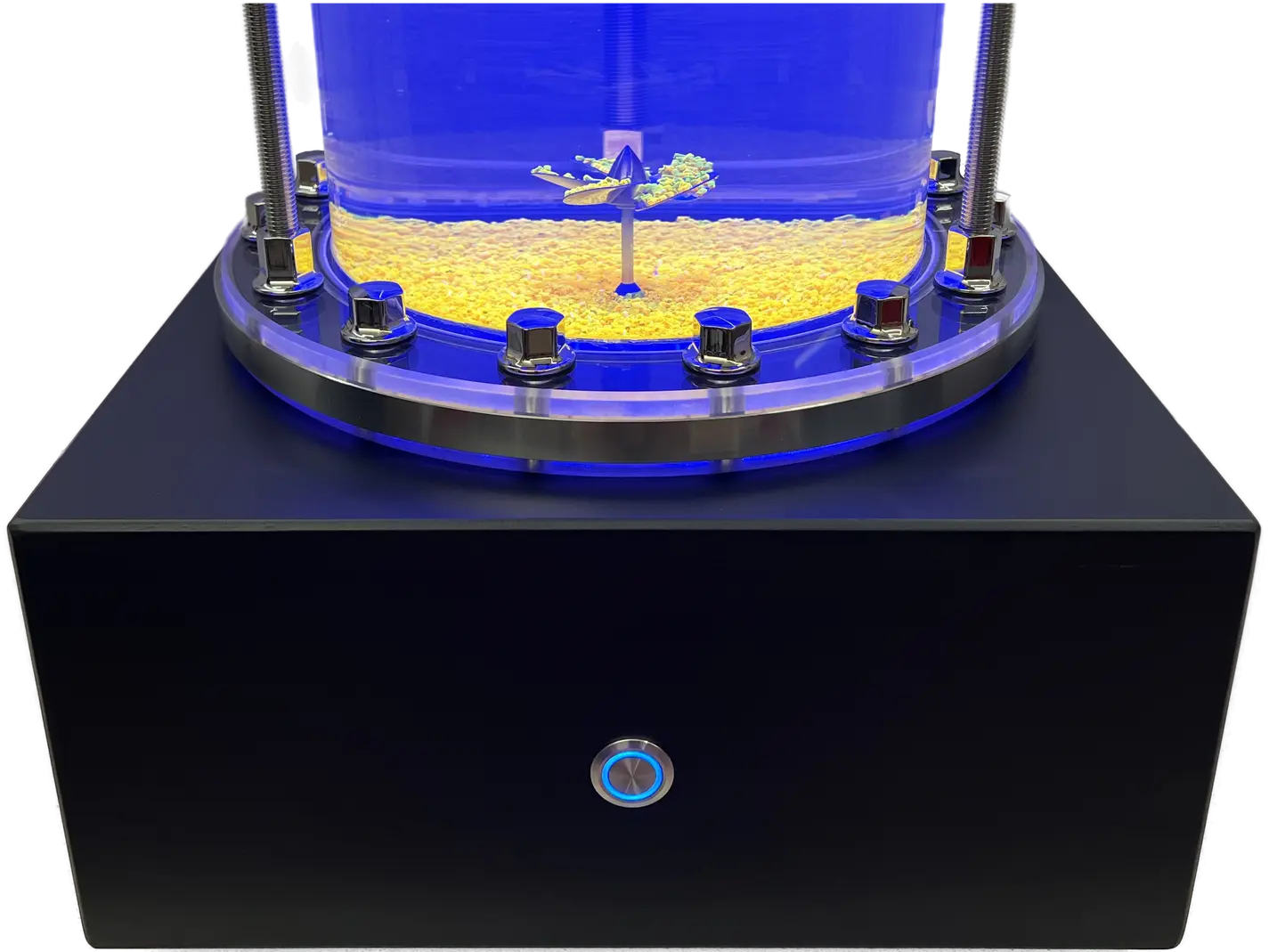

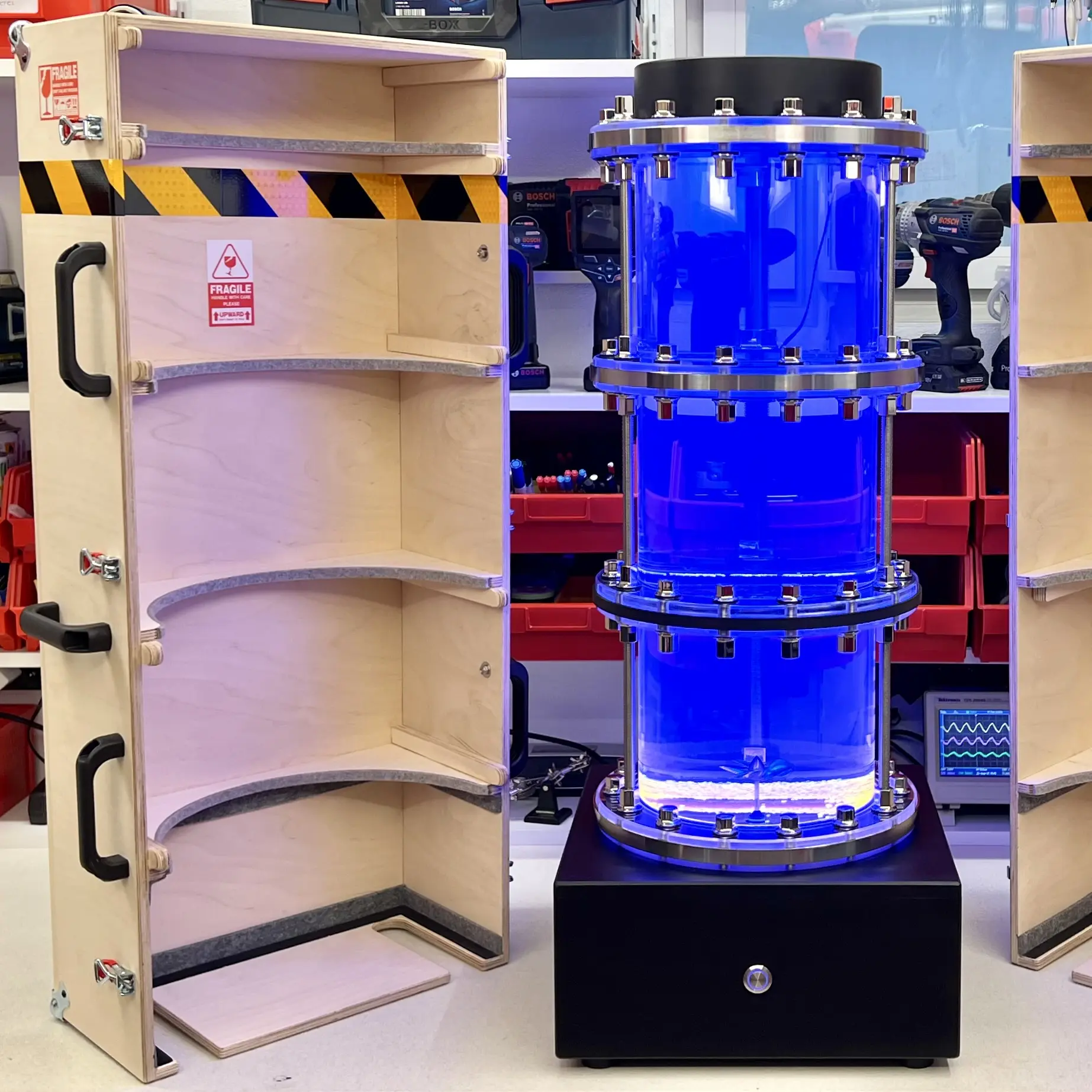

Real exhibit

From the digital design a precisely manufactured exhibit model made of acrylic glass, stainless steel and black-painted wood emerged in the real world.

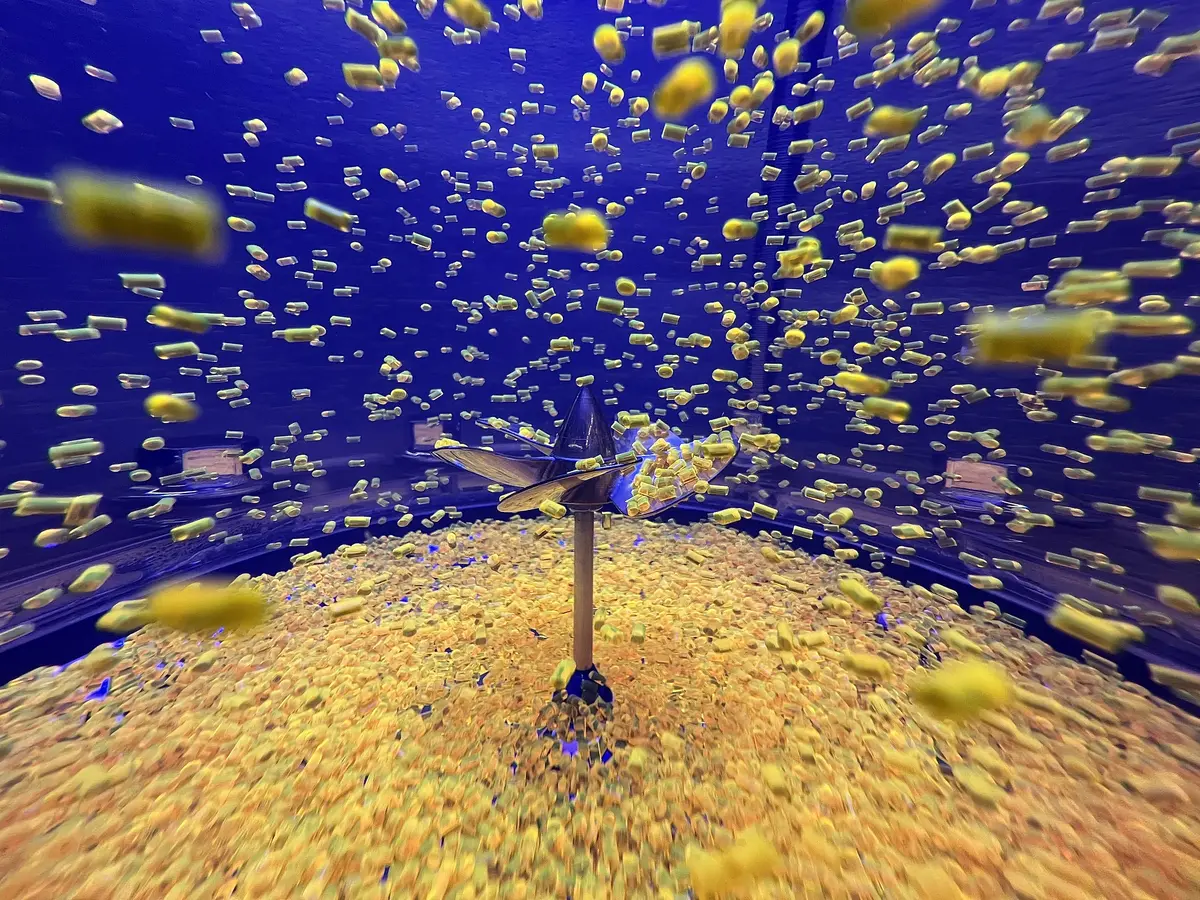

Exhibit in action

In action the exhibit unfolds its full effect. Flowing granulate and lighting effects create a dynamic that immediately attracts attention.

Uncompromising design - High-quality and pure

Blue shimmering water and orange glowing granulate reflect Freudenberg's corporate design. A deep black base, high-gloss polished stainless steel screws and clear acrylic glass emphasize purity and precision. The black light provides a modern, almost futuristic look and enhances the impression of innovation and high quality.

Eyecatcher - Fascination in the Water Stream

Already from a distance the demonstrator draws the attention of trade fair visitors. Glowing granulate clouds whirl in the water. A dynamic spectacle that immediately arouses curiosity. Technically exciting and visually impressive, the demonstrator is the eye-catcher at the trade show booth.

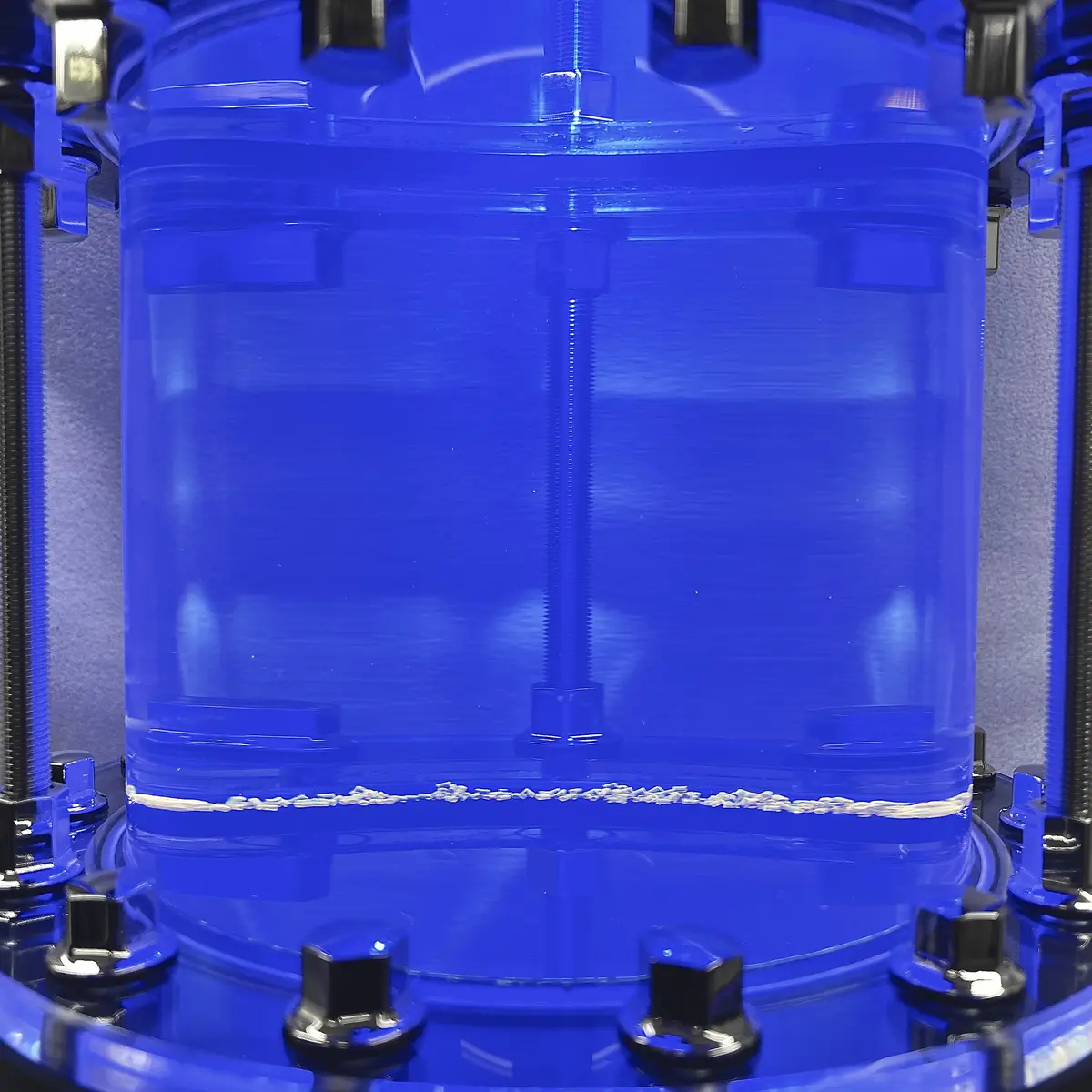

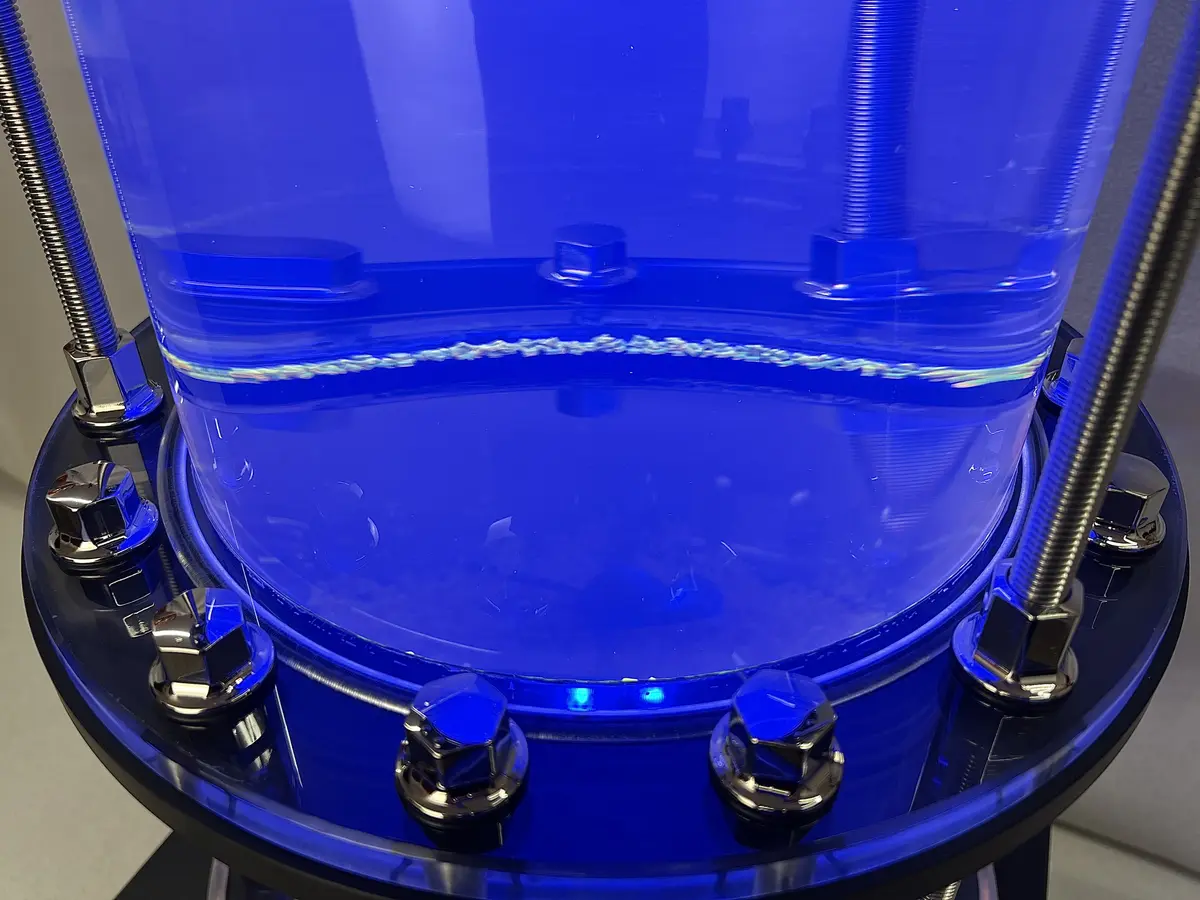

Focus - The Decisive Difference

At first glance the hygienic seal hardly differs from a standard seal. However, once installed it becomes visible how big the difference for hygiene really is. Standard seals create dead spaces where residues accumulate and hygienic risks arise. The hygienic seal from Freudenberg relies on precise geometries and smooth surfaces that allow complete cleaning and significantly reduce the risk of contamination.

In the following image the standard seal on which the fluorescent acrylic granulate settles can be seen below in the exhibit. The hygienic seal above, by contrast, remains residue-free.

The transparent flanges of the exhibit direct the gaze specifically to the seals. The overhang of the standard seal and the flush fit of the hygienic seal are clearly visible from all perspectives. The curved acrylic glass acts like a magnifying glass and enlarges the residues on the standard seal. This makes the advantage of the hygienic variant clearly apparent.

In the exhibit the overhang of the standard seal was deliberately made somewhat more pronounced so that the microscopic problem can be staged with coarse granulate.

Standard Seal

The overhang creates dead spaces

Hygienic Seal

The precisely fitting geometry prevents dead spaces

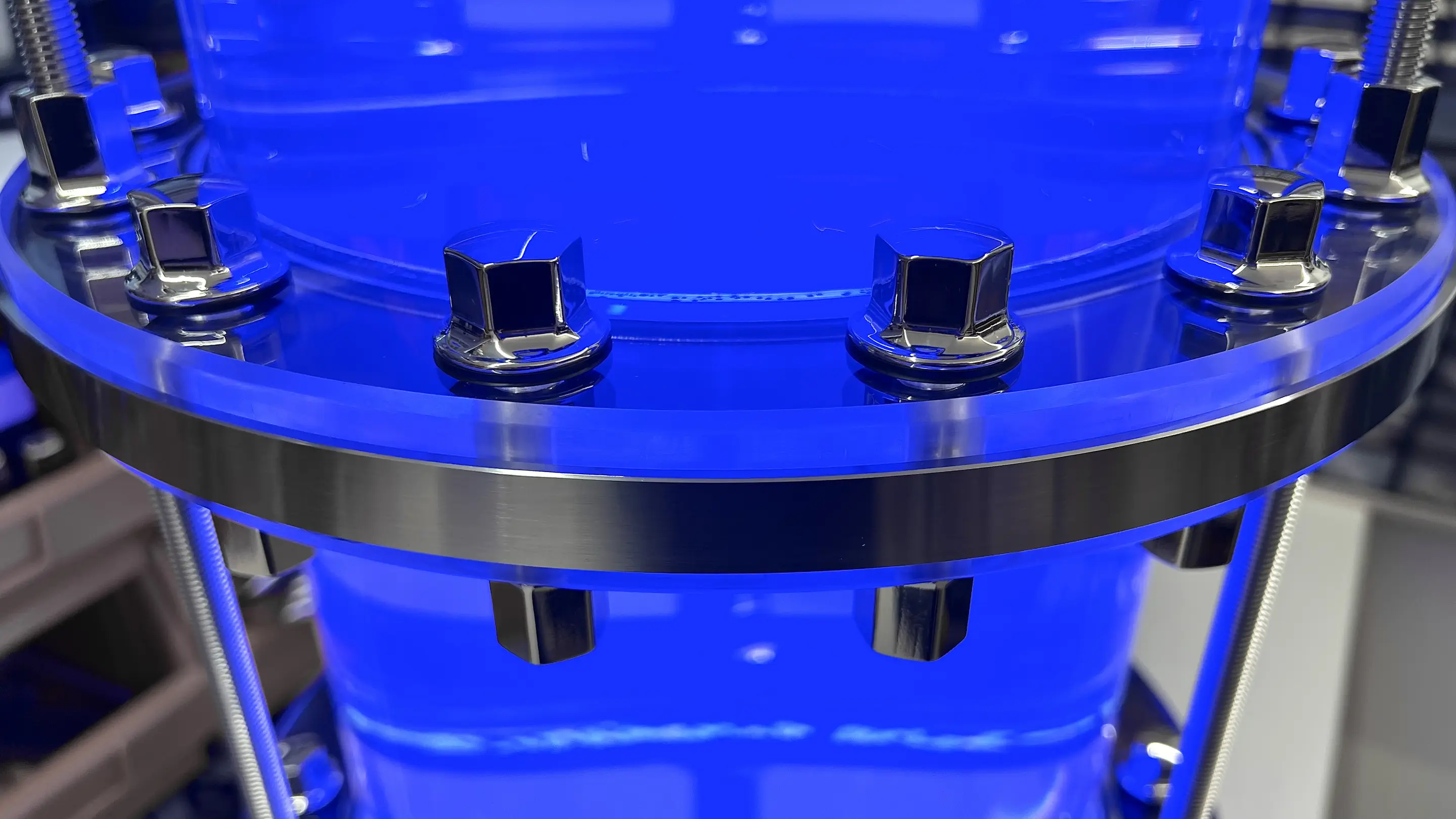

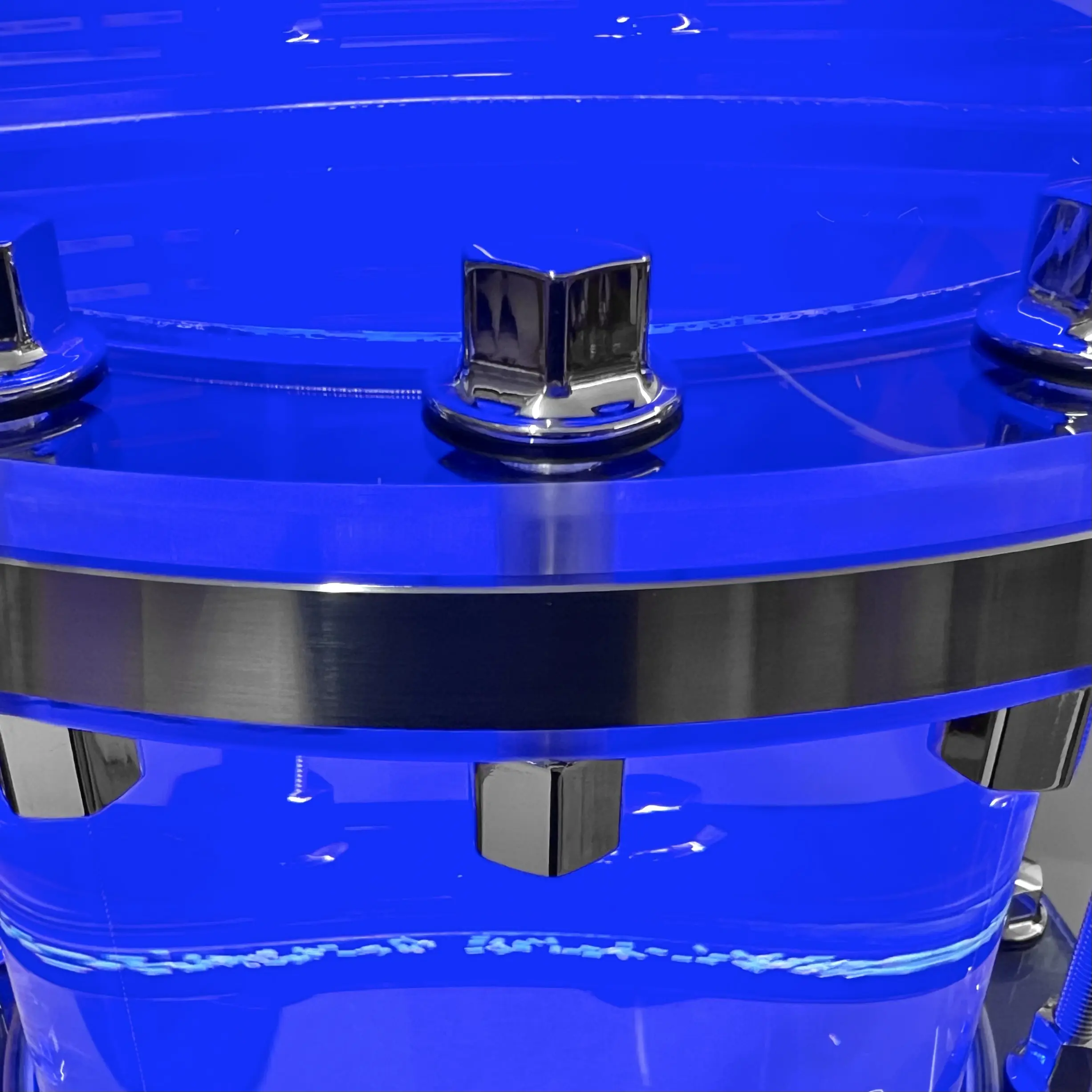

Noble stainless steel screws, high-gloss polished and certified

The high quality standards of Freudenberg should be reflected in the trade show appearance down to the last screw. Therefore EHEDG-certified fastenings made of polished stainless steel from the company Kipp were installed. A set of M12 fasteners consisting of a screw, a nut and a washer with seal costs around 50 euros net.

The above image shows a considerable total value of around 3,000 euros net and the following image the noble result from polished stainless steel combined with acrylic glass.

Development and Design of the Trade Show Exhibit

Before production the exhibit was fully designed digitally. This allowed function, design and proportions to be precisely coordinated and made the designs visually accessible to Freudenberg’s Hygienic Seal Team. The result was a reliable basis for a trade show exhibit that could be implemented on time and successfully.

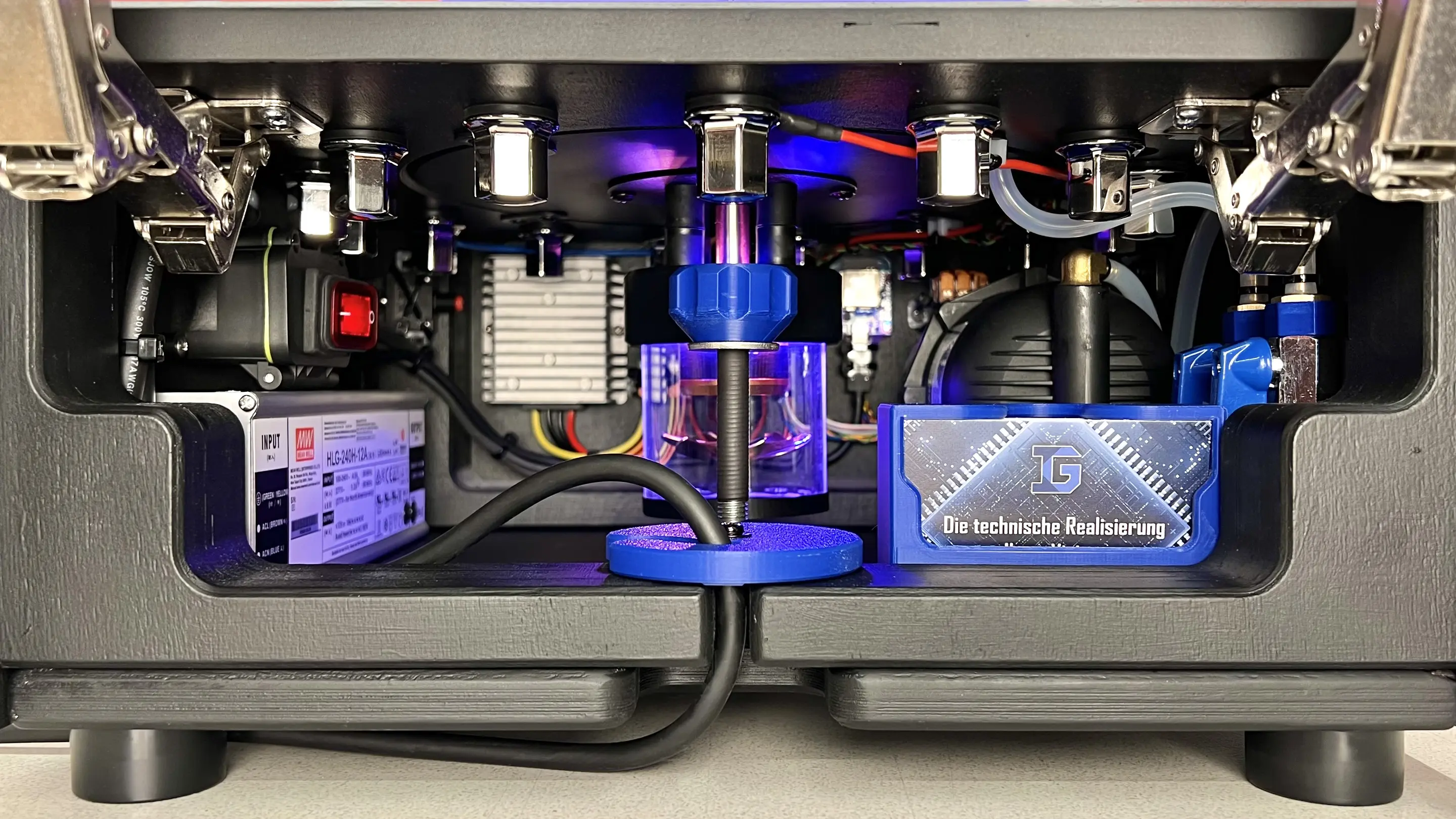

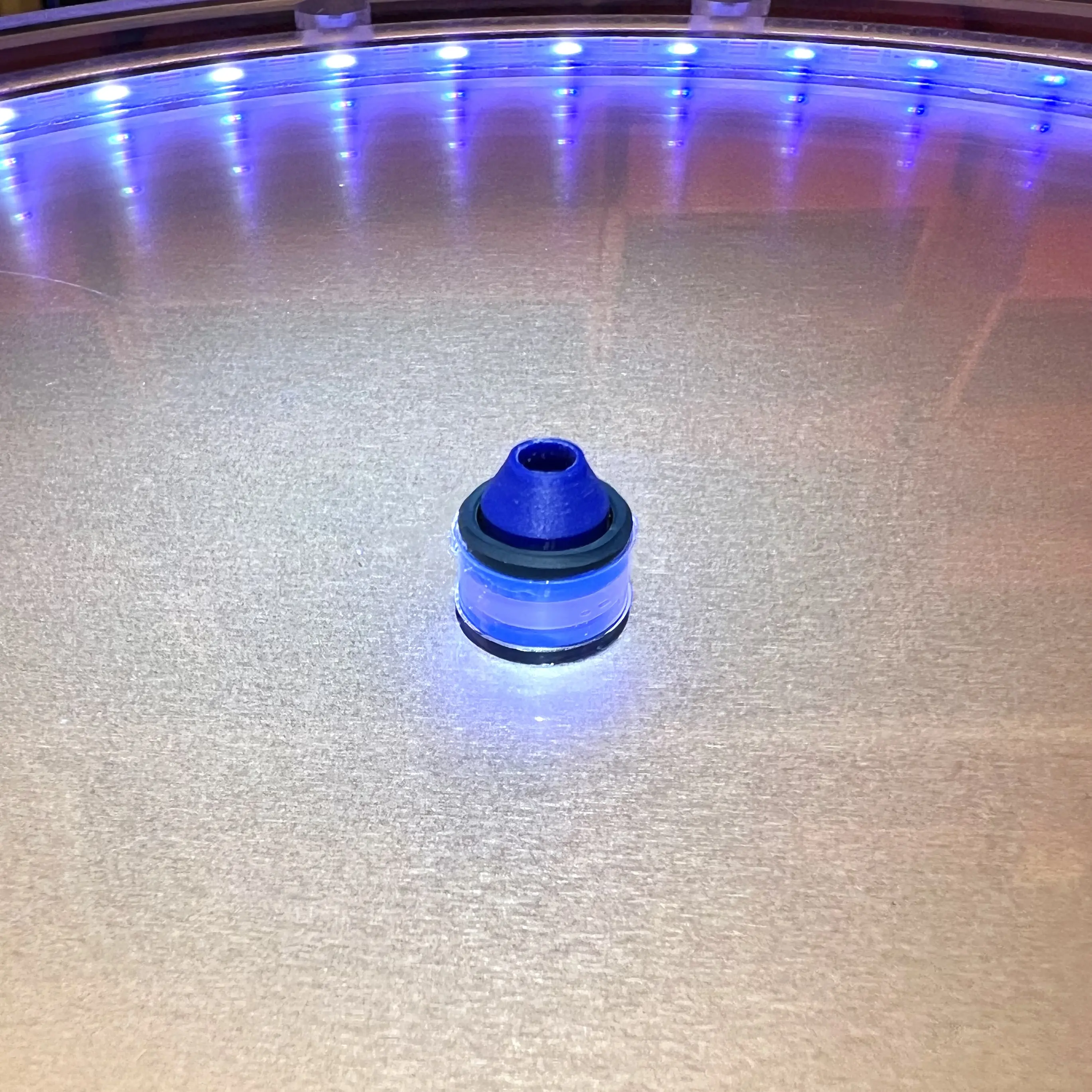

Drive unit with Freudenberg oil seal

The water screw is positioned inside the cylinder and is driven by a brushless electric motor in the model's base. Two consecutively arranged Freudenberg oil seals are used as radial shaft seals to seal the shaft feedthrough. Between them runs a full-ceramic ball bearing that guides the shaft precisely. The entire feedthrough is visible from the outside through the transparent acrylic glass base and is mirrored by the aluminum plate beneath it.

Brushless electric motor for the hydro screw

The water screw of the trade fair exhibit is driven by a maintenance-free outer-rotor motor that already develops high torque at low speeds and achieves peak outputs of up to 540 watts. The motor is mechanically decoupled by elastic rubber spacer studs, effectively reducing vibrations and structure-borne noise. An additional propeller supports cooling of the drive unit.

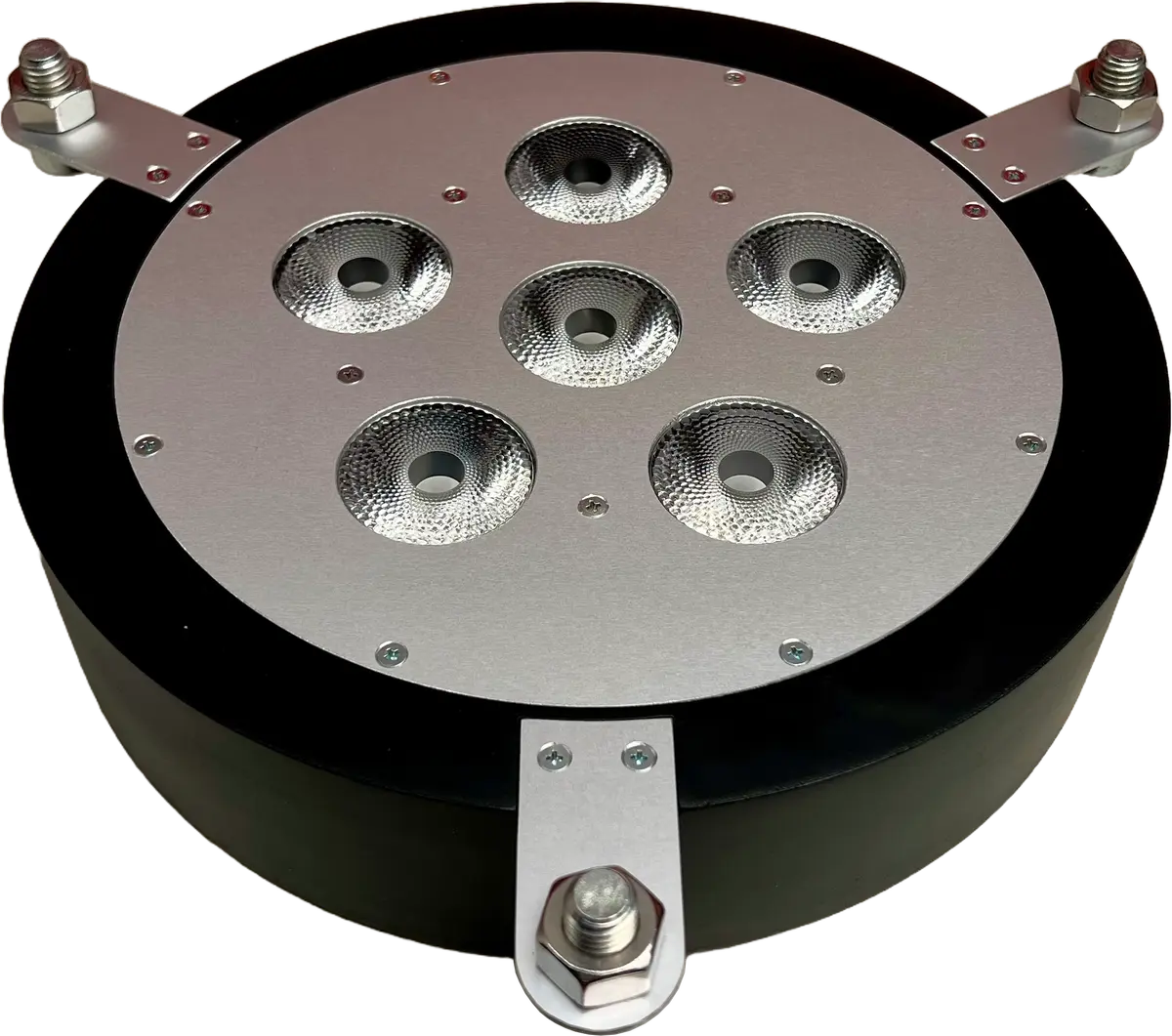

Impressive lighting effects with blacklight via RGBAW+UV LEDs

Six RGBAW+UV LEDs with a total output of 72 watts enable flexible lighting effects and reproduce not only red, green and blue but also amber, white and UV with high color fidelity. The blacklight makes the fluorescent granulate glow impressively. The unit is housed in a black-painted, 3D-printed enclosure with a CNC-milled aluminum front panel. The power supply is provided via two threaded rods, while a third transmits the DMX signal for precise control.

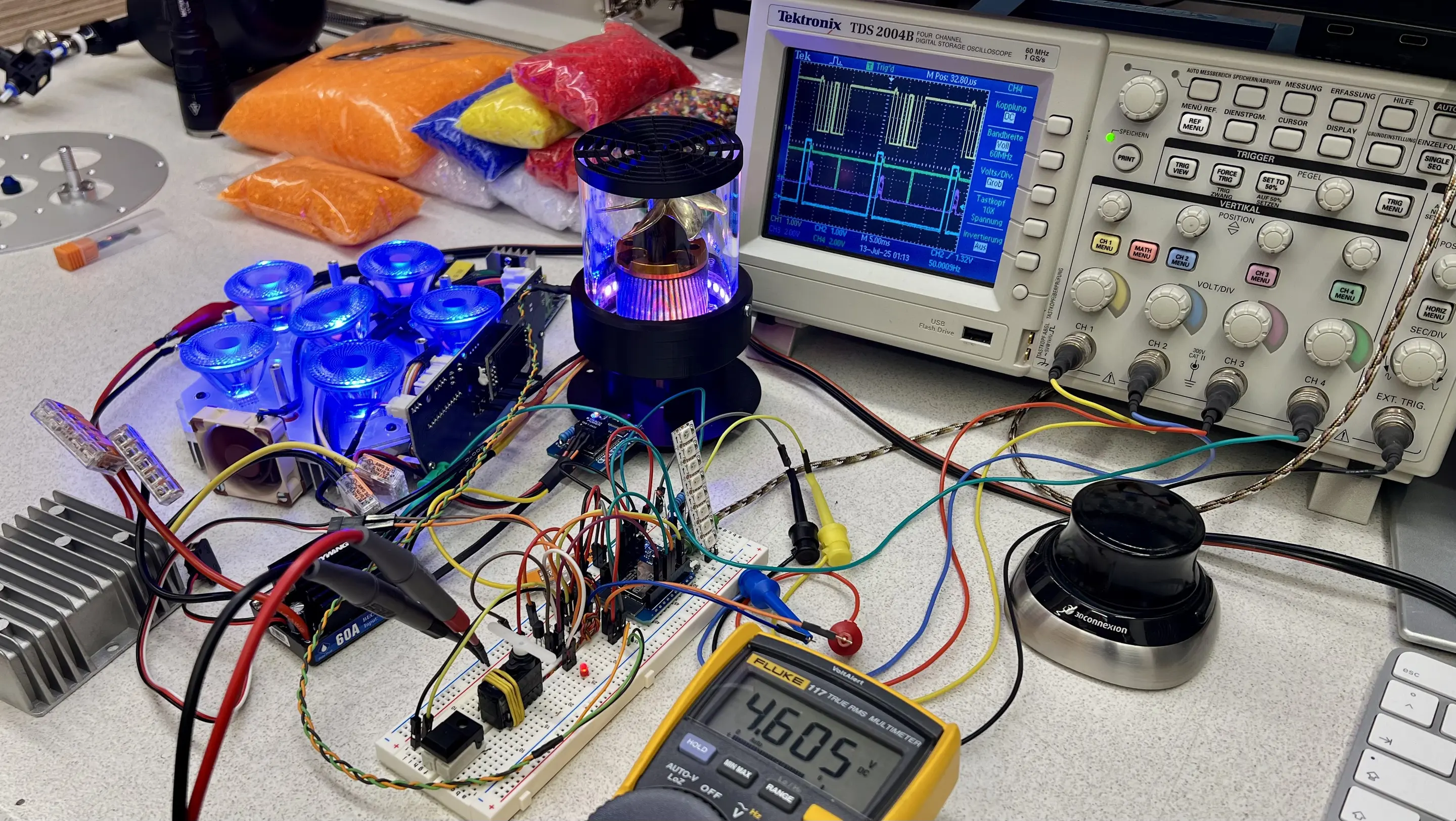

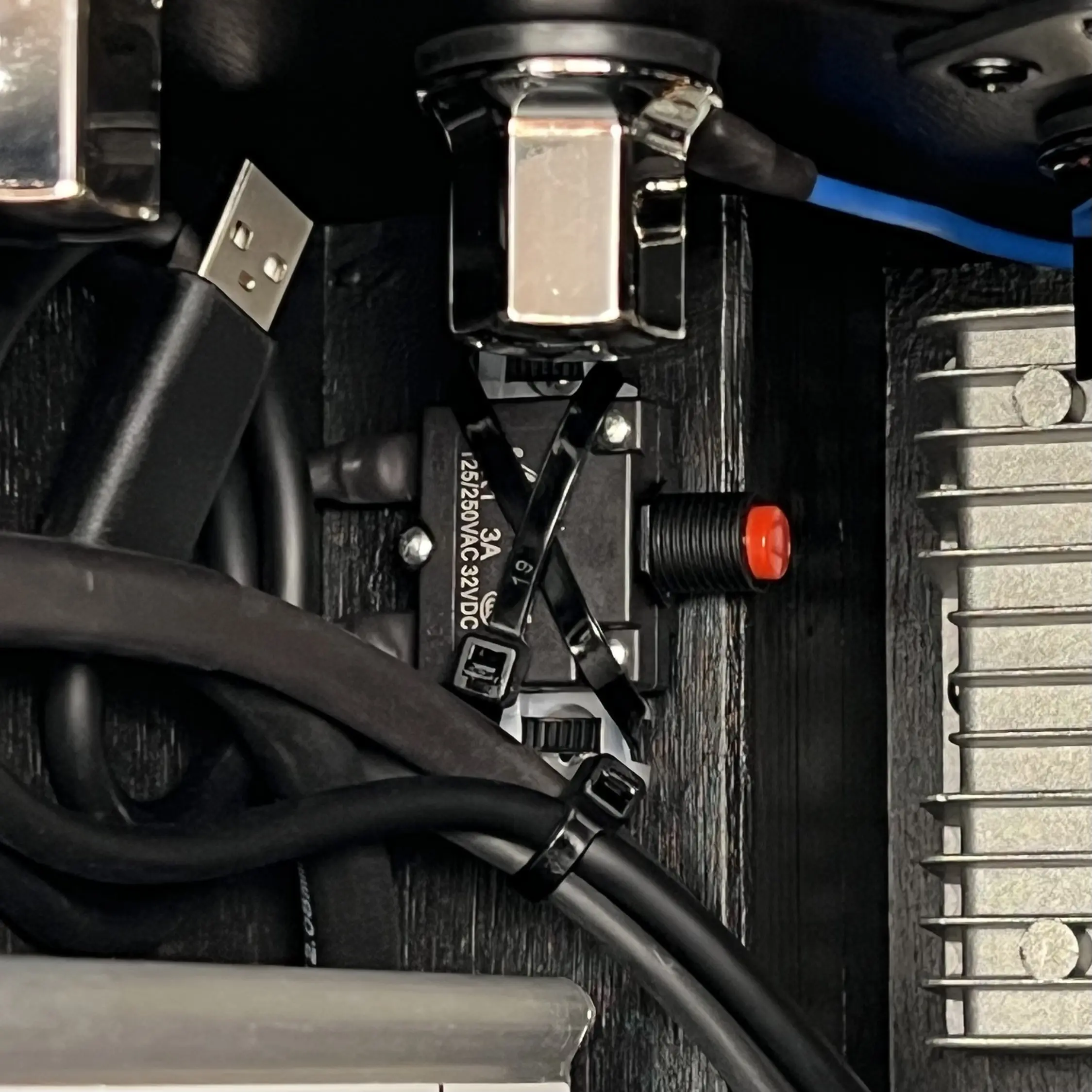

Microelectronics and control of the trade fair exhibit

The drive and LED unit of the exhibit are controlled by an ESP32 microcontroller with a clock frequency of 240 MHz. The software is developed in C++ and coordinates motor movements and lighting effects. The sequence starts automatically at an adjustable interval or manually via a push button in the base. First, the granulate is stirred up by a short reverse run and then distributed throughout the cylinder with a fast forward run. After settling, a slow reverse run ensures that the mirror at the bottom is cleared and the oil seal becomes visible.

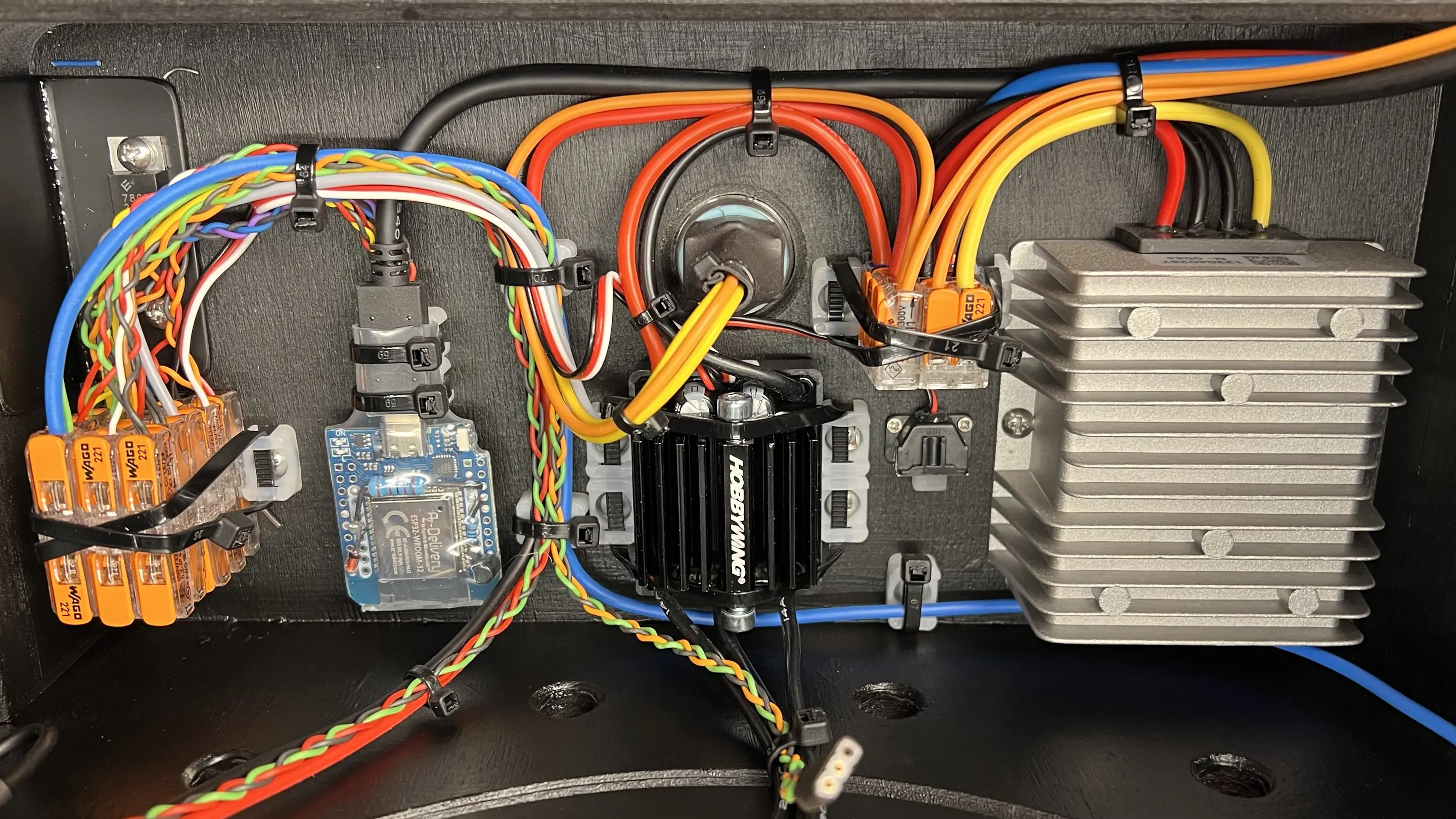

Power electronics and power supply

For the power electronics, a high-quality brushless controller from the model hobby sector is used. It converts the 12 volt DC from the power supply into a frequency-controlled three-phase current for the motor. The LED unit is operated at 24 volt, which is generated via a boost converter. An additional voltage regulator supplies 5 volts for the LED strips in the base.

Under the hood of the trade fair exhibit

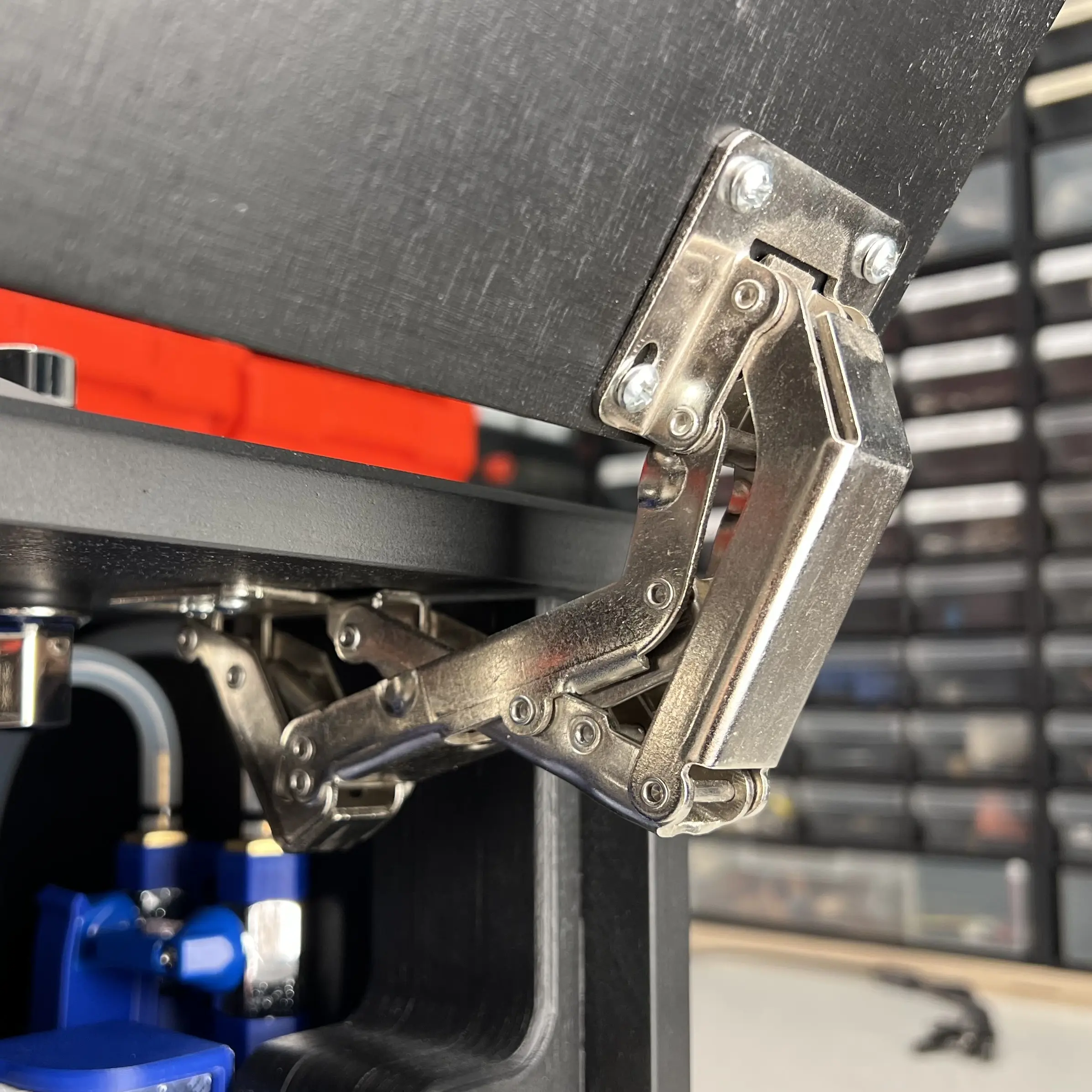

The Hygienic Seal Demonstrator can also be viewed from the inside. The back panel can be folded up via two hinges, making the interior freely accessible. In addition to the drive and electronics, there are accessory components and a pressure compensation tank inside that reliably compensates volume changes of the water during temperature fluctuations.

The trade fair model in individual parts

Before assembly, all individual parts of the trade fair exhibit were carefully laid out and counted to detect missing components early.

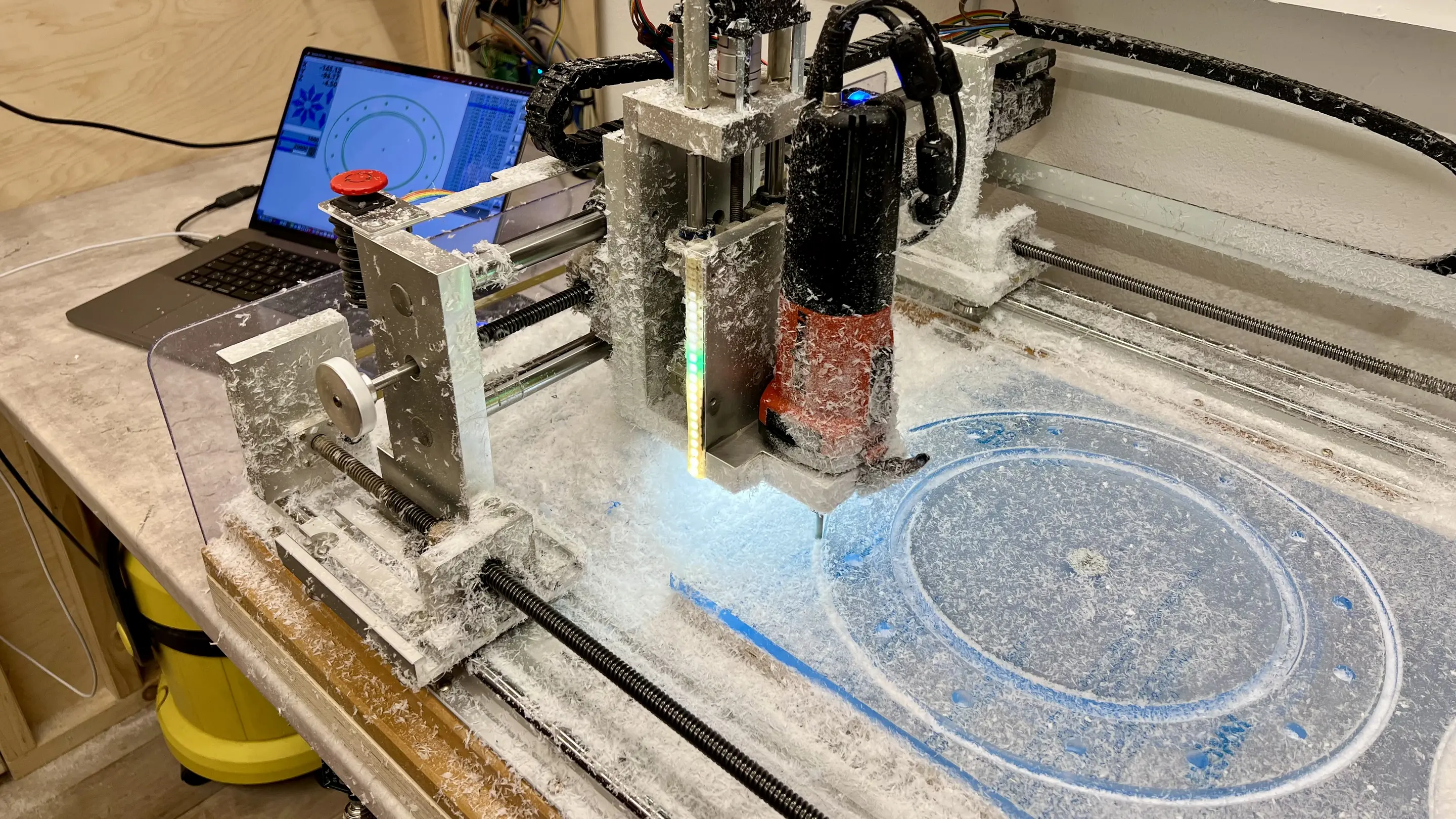

Manufacture of the flanges from acrylic glass

All eight flanges of the trade fair exhibit were precisely CNC-milled from transparent acrylic glass in several passes. Despite the simple geometry, the challenge was to achieve the appropriate surface characteristics for chamfers, grooves, visible surfaces and bonding surfaces.

For production, the use of several cutter types was required. Employed were single-flute, two-flute, tapered end mills, countersinks, and ball mills, to achieve the required contours and surface qualities. The circular groove for the centering bead of the seals was produced by helix milling, in which the cutter slowly moves in small circular motions. This resulted in a slightly oval geometry that deliberately gives the EPDM seal room for elastic deformation.

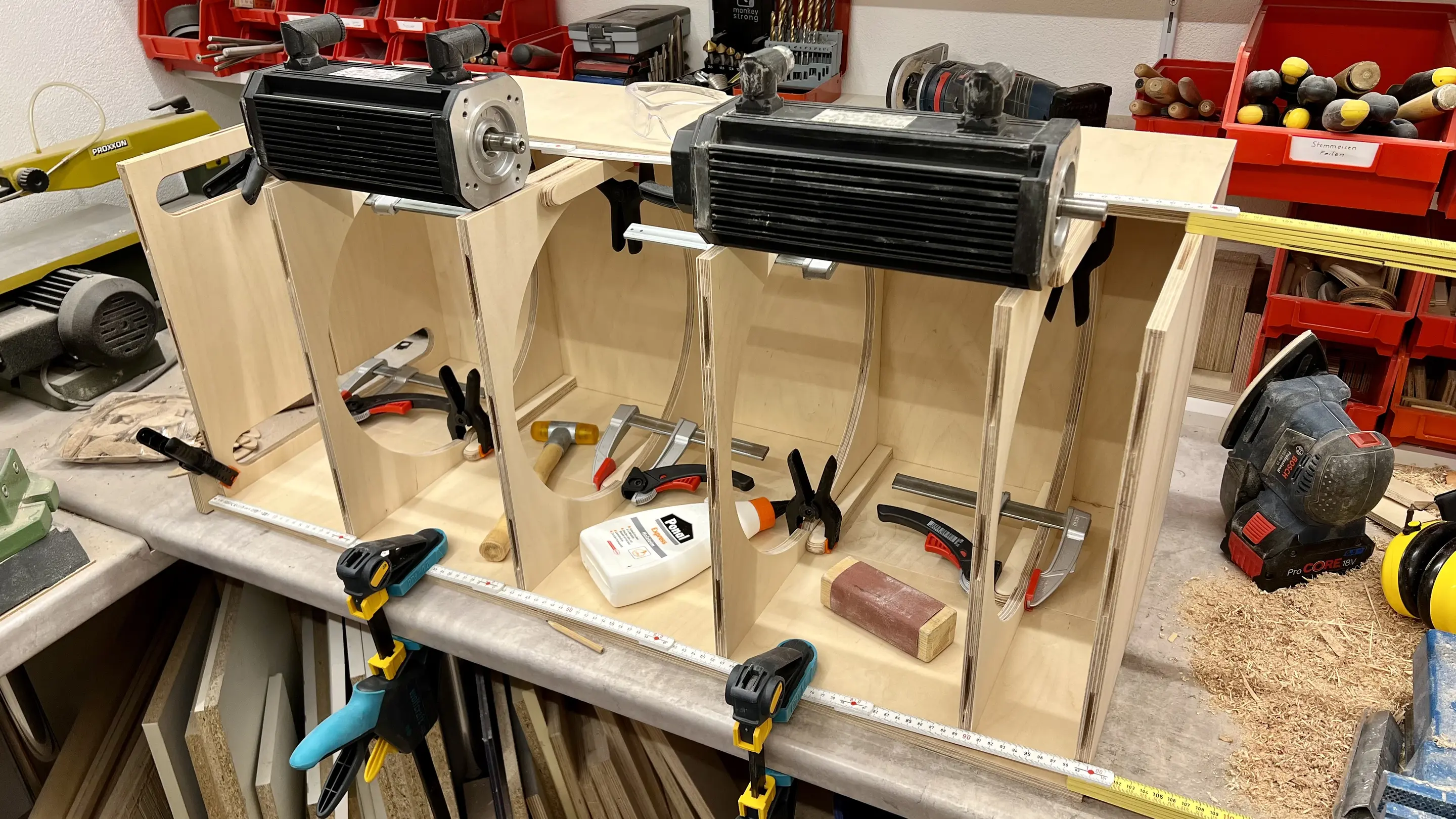

Manufacture of the base and transport crate from wood

The base of the trade fair exhibit was precisely manufactured from wood on the CNC machine. The 15 mm thick multiplex panels are glued together with loose tenons, ensuring a permanently stable connection. The surface is coated with a matte, deep-black two-component lacquer that looks high-quality while being resilient and impact-resistant.

To ensure that the two shells of the transport crate fit together precisely, the second shell was aligned exactly to the first during gluing.

Transport crate optimized for trade fair use

For trade fair use, a robust wooden crate made of 12 mm thick multiplex was produced to enable secure transport and quick assembly of the exhibit. Two precisely fitting wooden shells are slid over the demonstrator from both sides and secured with toggle latches. This allows the 65 kg heavy exhibit to be lifted directly using ergonomic handles, without first having to transfer it into another crate.

Since each individual pipe segment is supported all around, the trade fair model can be transported both standing and lying down. The fluid remains in the system, draining is not necessary for careful transport. For road transport, it is additionally recommended to place a foam pad between the pallet and the crate to further dampen shocks.

Real-time demo of the trade fair exhibit

The unedited 3-minute video shows the complete program sequence of the Hygienic Seal demonstrator. From the agitation of the granulate to its distribution and setting under UV light, to clearing the mirror floor showing the oil seal. The sequence exactly matches the presentation at the trade show booth.

Ooh, Aah, Wow! Customer magnets for your trade show booth.

The Glaser engineering office develops and manufactures custom exhibition exhibits. As eye-catchers they attract visitors' attention at your booth with a curious “Ooh”. The benefits of your product become clear and tangible on the demonstration model with an amazed “Aah”. With a final “Wow!” you, your product and your brand remain memorable.

Technical details and notes for the trade show team

The following section describes the technical details of the trade fair exhibit and contains additional notes for the trade show team on handling.

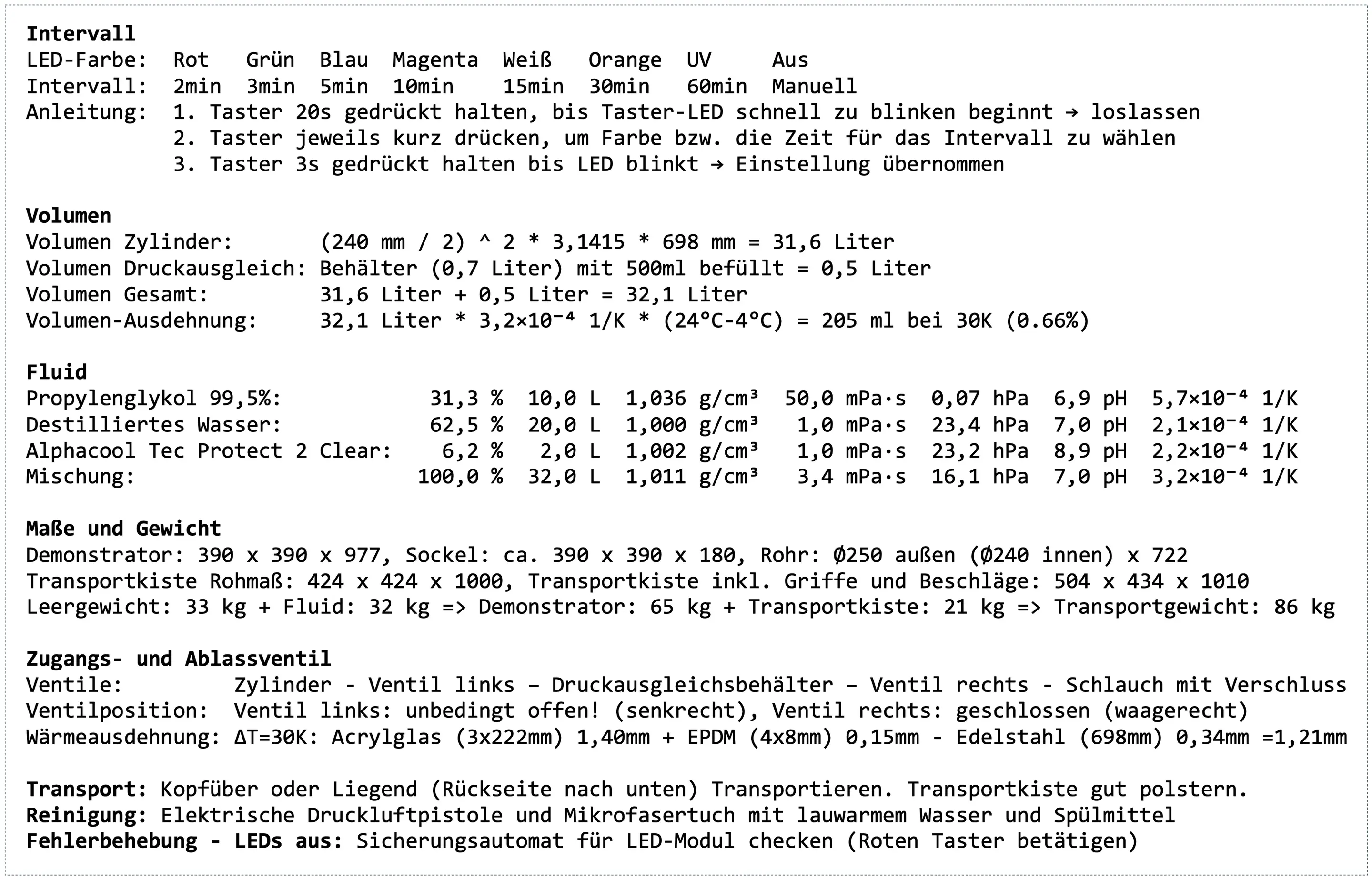

Dimensions and weight

Exhibit: 390 x 390 x 977 mm

Base: 390 x 390 x 180 mm, Pipe: Ø250 x 722 mm

Transport crate raw dimensions: 424 x 424 x 1000 mm

=> Crate incl. handles and fittings: 504 x 434 x 1010 mm

Empty weight: 33 kg + fluid: 32 kg

=> Exhibit: 65 kg

Exhibit weight: 65 kg + Transport crate: 21 kg

=> Transport weight: 86 kg

Stainless steel pushbutton with LED ring

When the pushbutton is pressed, the following sequence starts:

- 1s - Bright white flicker of all LEDs to attract attention.

- 5s - Reverse run, to loosen granulate (5s)

- 2s - Short strong forward run, to distribute granulate

- 5s - Reverse run, to prevent vortexing

- 77s - Pause to allow the granulate to settle

- 50s - Several short reverse pulses, to clear the mirror floor, so the sealing ring becomes visible. (This step is skipped for the 2 min interval.)

- Restart by button press or by the timer

(e.g. after 3 min)

If the button is pressed during a running sequence, bright red light directs focus to the deposited granulate.

Setting the interval

The sequence can be started manually by button press or automatically by a configurable interval. To select the duration, follow these steps:

- Hold stainless steel button for 20s, until LED blinks rapidly

→ release - Choose color or the time for the interval

→ briefly press stainless steel button - Hold stainless steel button for 3s until the LED blinks

→ setting accepted

The following settings are possible in item 2:

Red → 2min*, Green → 3min, Blue → 5min, Magenta → 10min, White → 15min, Orange → 30min, UV → 60min, Off → Manual

*With interval "2 min" the clearing of the oil seal is skipped in the program sequence

Fluorescent acrylic granulate

The fluorescent PMMA granulate glows bright orange under UV light and thus provides a high contrast to the complementary color of the slightly bluish glowing fluid. The cylindrical particles (grain size approx. 3 × 2 mm) are slightly denser than the used fluid, sink at about 1 cm/s and rest on the bottom again after roughly 80 seconds. Due to their round shape the grains roll off the protruding seal when swirled up and then sediment again.

Durable fluid

The fluid consists of the following components to be as durable as possible with minimal maintenance:

- 62.5% distilled water - provides optical clarity and, with low viscosity, good flow properties.

- 31.25% propylene glycol - lowers water activity for natural preservation, reduces evaporation and supports the lubrication of the shaft seal.

- 6.25% Alphacool Tec Protect 2 Clear - forms a thin protective film on brass and stainless steel, keeps the pH slightly alkaline and, together with antioxidants, acts against optical aging under light.

- 0.5 ml SpaBalancer AntiFoam - serves as a silicone-based defoamer to prevent the formation of water bubbles on the pipe wall and on the acrylic granulate and thus to prevent floating.

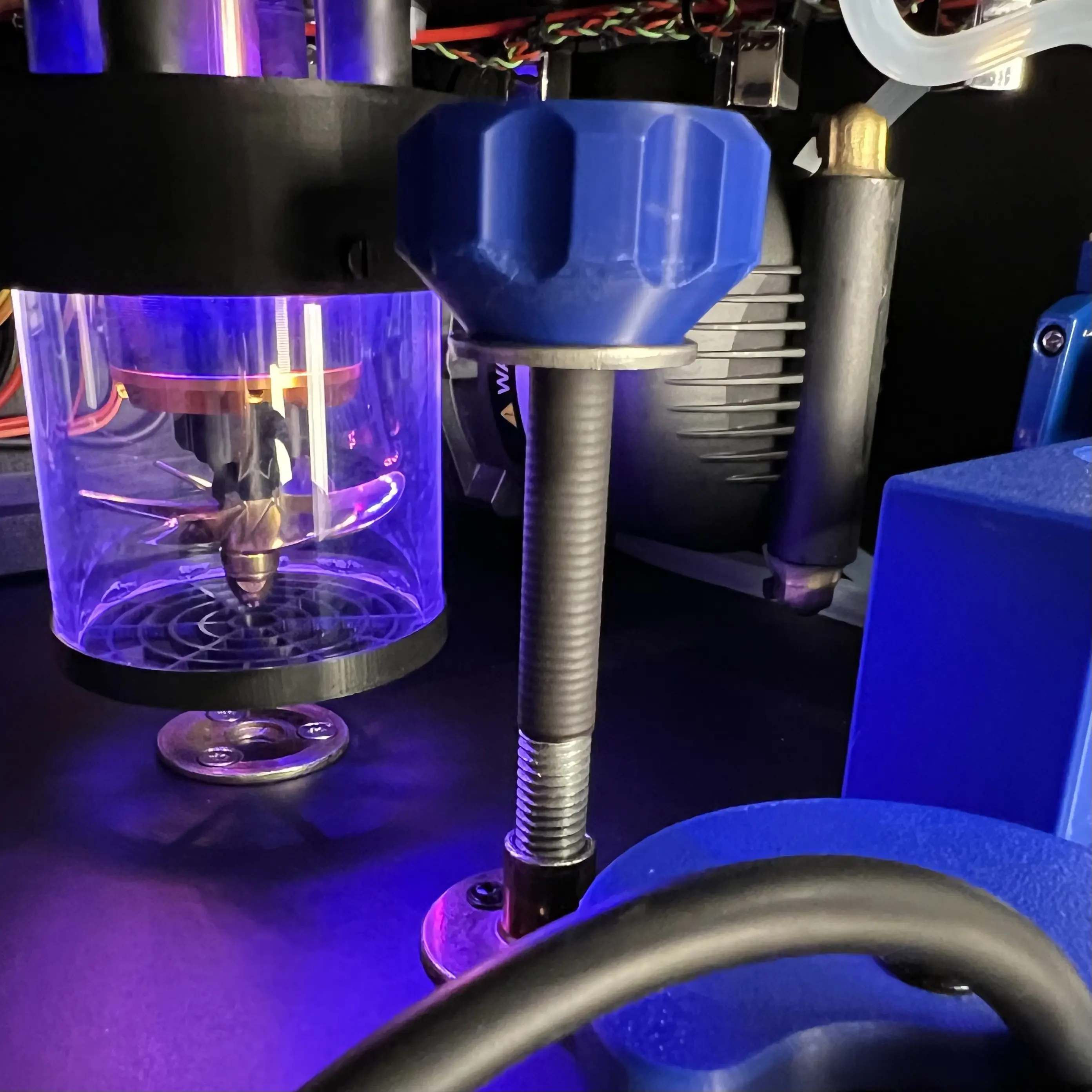

Shaft feedthrough with oil seals

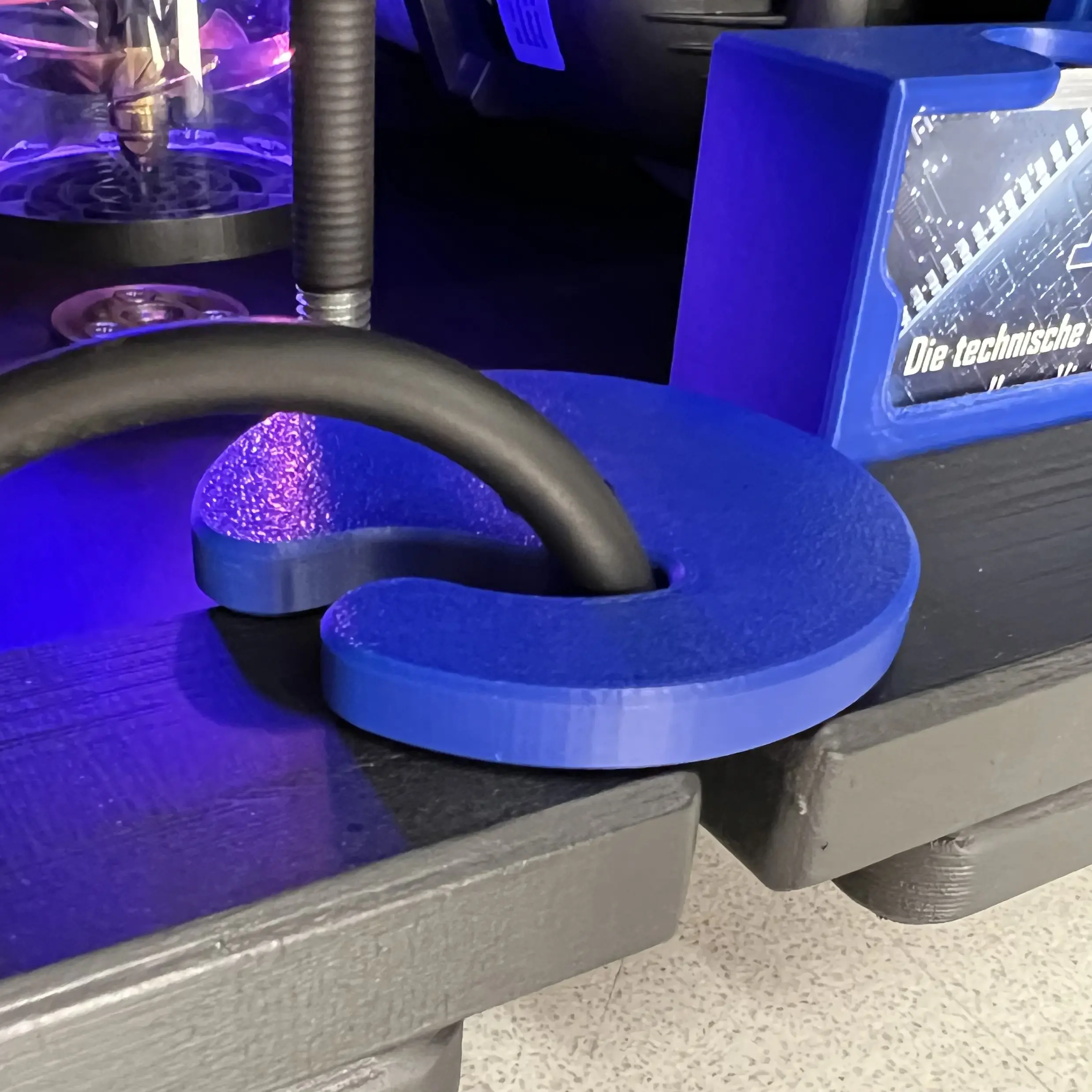

The shaft feedthrough was realized using two oil seals (4×12×0 BA – 72 NBR 902 – 4041107) from the company Freudenberg. Between the radial shaft seals the 4 mm stainless steel shaft is guided precisely by a solid ceramic ball bearing (4×12×4). The space between the two seals is completely filled with silicone grease to ensure reliable lubrication. For the upper seal the spring was removed and it was installed so that the static water pressure increases the radial sealing pressure. A small 3D-printed cuff made of blue PETG protects the seal from incoming granulate or contamination.

At the bottom of the container there is a reflective surface behind the lowest acrylic flange that reflects the light coming from above. This additionally illuminates the suspended granulate from below, which enhances the brightness.

Maintenance-free drive

The water screw is driven by a brushless and thus maintenance-free outer-rotor motor with up to 540 watts peak power at 12 volts. The motor is decoupled via elastic spacer bolts, effectively reducing vibrations and structure-borne noise. An acrylic tube with a protective grille prevents any contact, while an additional propeller handles the cooling. For maintenance of the oil seals the entire drive unit can be easily removed.

Waterproof power supply

The exhibit's power is supplied by a high-quality 12V switching power supply from the company Mean Well. With IP65 protection rating both the power supply and the potted cable are reliably protected against water. The on/off switch with integrated power LED is installed on the secondary side.

Volume and fluid

The acrylic cylinder has a capacity of 31.6 liters. With a temperature change of 20 Kelvin the fluid expands by 0.66%, which corresponds to a volume of 205 milliliters. This expansion volume is absorbed by the expansion tank, which with a capacity of 700 milliliters provides sufficient reserve in both directions. The permanently atmospherically ventilated tank was filled with 500 ml of fluid at 20 °C, so that it can reliably compensate for volume fluctuations. Since the hose connection at the cylinder bottom is the only opening, the water remains in the acrylic cylinder even with the drain valve open. As a result the static pressure at the oil seal is almost zero, which is a significant advantage for the tightness of the oil seals.

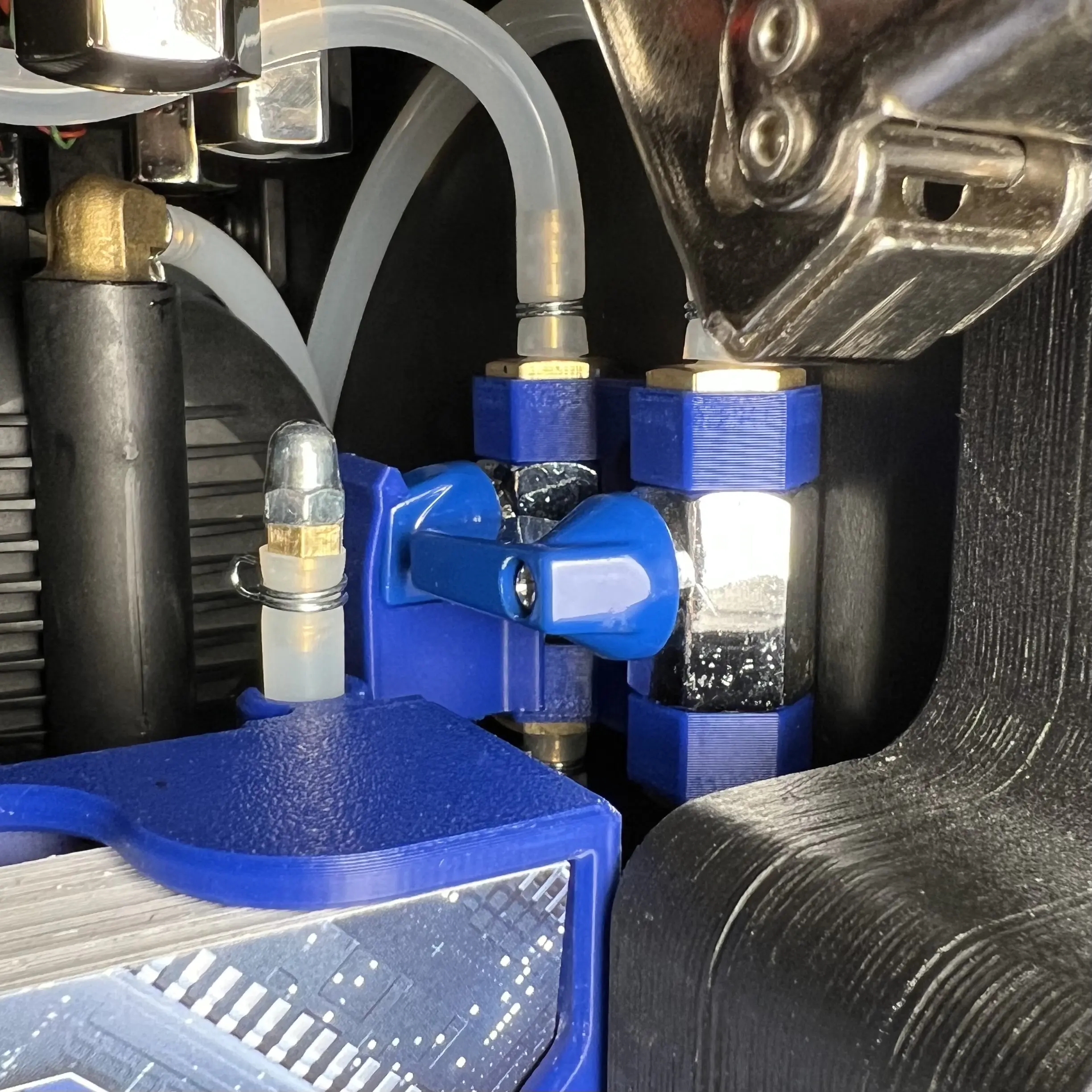

Access and drain valve

The two water valves are intended solely for service and maintenance purposes and must not be operated during the exhibit’s operation or transport. The access valve on the left connects the pressure-compensation tank to the water reservoir. It is fitted with a safety clip and must remain permanently open to ensure continuous pressure equalization. On the right is the drain valve, which is connected to a drain hose. Its end is secured with a plug and held by a clip.

Bleeder screw

The bleeder screw is intended solely for service and maintenance work. There is a bore in the upper full flange of the exhibit that reaches into the interior of the water reservoir. This access can be opened via a grub screw to release remaining air bubbles. It must be noted that the entire system must be brought to slight overpressure via the drain hose.

LED module protection

The power supply for the LED module above the cylinder is routed via three threaded rods. The front-left rod serves as ground (GND), the front-right as the DMX data line, and the rear one transmits the 24 V DC supplied by the DC/DC converter. All conductors are circuit-design protected against conductor-to-conductor contact and short circuits, ensuring safe operation. Additionally, an integrated circuit breaker secures the power supply. In the event of a trip, it can be easily reset by pressing the red button.

Threaded flange for fastening

To securely fix the exhibit to a table, an M10 internal thread is provided in the center of the base plate of the pedestal. Through this, the demonstrator can be fastened to the table from below with a screw. For some tolerance in positioning, a 20 mm diameter hole in the table is recommended. A suitable screw with washer and hand knob is designed for table thicknesses of 20 to 45 mm and is stored in the pedestal of the exhibit. It is important that the maximum insertion depth of 35 mm is not exceeded to avoid collision with the drive unit, which is also arranged centrally.

Cable routing with strain relief

The cable routing of the exhibit is designed to run invisibly under the base. To pass the Schuko plug through, a hole with min. 42 mm diameter is required in the tabletop. Behind the base cover there is a groove through which the supply cable can be pulled out to the required length. Using a 3D-printed rotary disk, the cable can be secured, so the appropriate length is always available.

Water-protected supply cable

The 3-meter 230 V supply cable is connected directly to the waterproof IP65 power supply without an intermediate coupling to provide maximum protection against moisture. For transport, the supply cable is stored in the pedestal of the exhibit.

Accessories in the transport case

In the exhibit’s transport case there is an electrically powered air duster with which dust on the acrylic flanges between the screws can be quickly and easily removed. The box also contains a small toolbox and various accessories that simplify assembly.

Small toolbox

As compact as the toolbox is, the maintenance effort is equally low. The water remains permanently in the exhibit and is durable for years. For assembly and possible emergencies, the following items are nevertheless included:

- 18 mm socket and ring spanner made of plastic to protect the stainless steel screws

- USB power adapter with USB-C cable for charging the electric air duster

- Microfiber cloths for cleaning the transparent acrylic glass segments

- Hex key for the venting valve and for retightening the set screw of the shaft coupling

- Test strips for checking pH value

Torques of the fittings

The bolts and nuts of the flanges were tightened alternately and in a cross pattern with the following tightening torques.

- Lid: 3.6 Nm

- Top: 3.6 Nm

- Bottom: 3.8 Nm

- Base: 4.5 Nm

Flip lid with lift hinges

Via two internal surface-mounted hinges, the lid of the base back panel can be swung up 170°. This makes the interior with the exhibit's technology and accessories comfortably accessible. For possible repair and maintenance work, the entire base plate of the pedestal can also be removed.

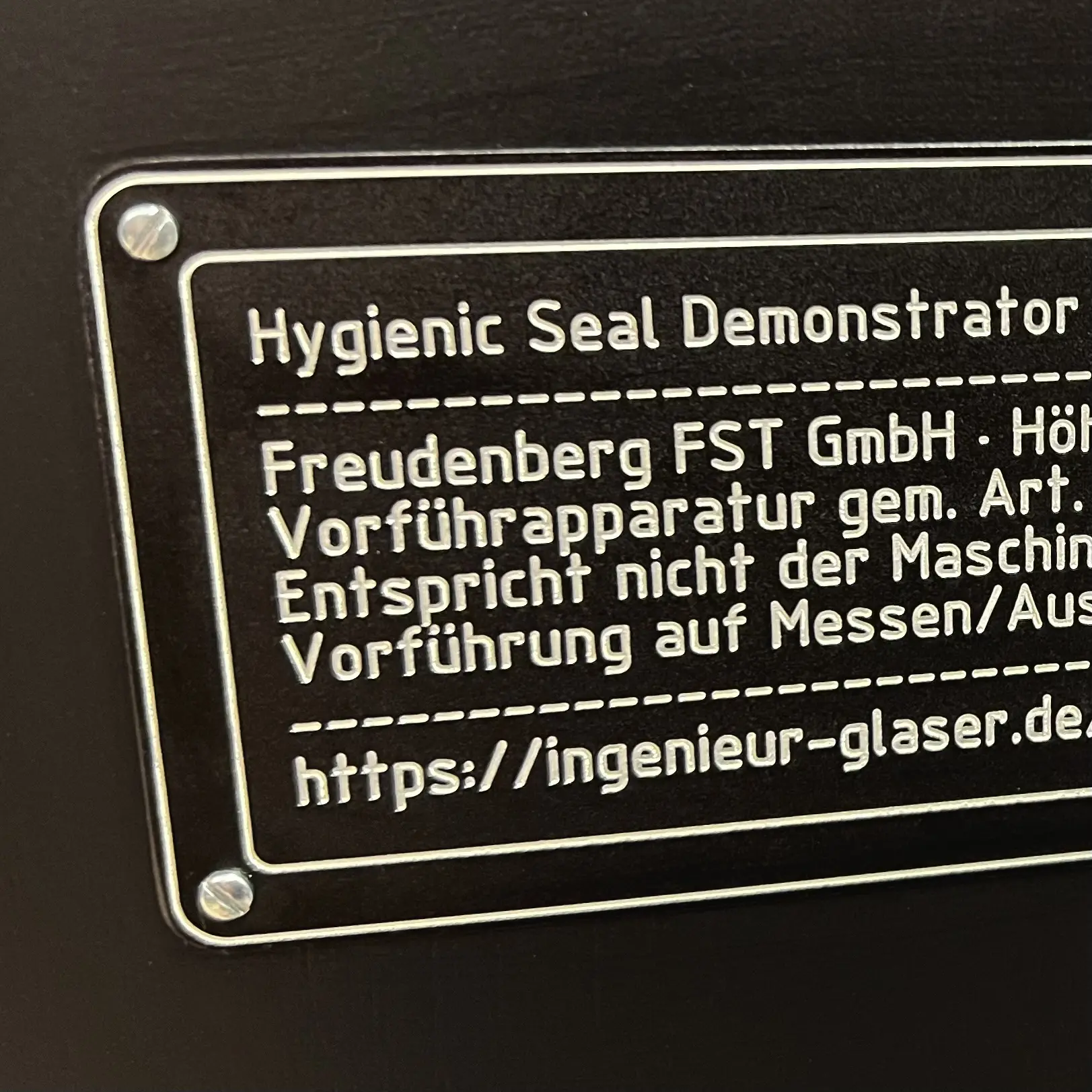

CNC-engraved nameplate

The permanently attached nameplate defines the intended use of the exhibit and contains the relevant information on year of manufacture, project and operator. It clearly indicates that this is a demonstration apparatus for use at trade shows and exhibitions and governs the conditions for proper operation. The URL given below points to this project page.

All technical data on the exhibit

A notice plate is mounted on the inside of the flap at the back of the exhibit's base, providing the trade show team with all important technical information at a glance. It contains information on interval control, volume, fluid composition, dimensions and weights as well as valves, transport and cleaning.

The exhibit in augmented reality (AR)

The Hygienic Seal Demonstrator can be experienced not only live at the trade show but also virtually in augmented reality. With a smartphone the model can be placed in the room and viewed from all perspectives without an additional app.

Virtual trade show exhibit

-

Scan the QR code with the camera app

-

Open the displayed link

-

Select the cube icon at the top right

-

Point the camera at the floor

-

Tap to place

More 3D models and renderings

The following are renderings of the trade fair exhibit shown in large format. They were calculated over several hours to reproduce reflections, shadows, and light refractions particularly realistically.

THANK YOU!

A big thank you to the Hygienic-Seal team from Freudenberg for the trusting and appreciative cooperation. The close exchange and strong teamwork made this project a real success in a short time. Thank you for the refreshing meetings, the personal visits to the workshop, and the warm welcome at the booth.

Exhibition model for hygienic seals - Freudenberg booth at the drinktec trade fair in Munich

🥳️ At the drinktec trade fair in Munich, the Hygienic Seal Demonstrator attracts visitors to the Freudenberg booth. Under UV light it becomes visible how crucial hygienic seals are for cleanliness and process safety.

🙏️ A big thank you to the Hygienic Seal team at Freudenberg for the trusting and appreciative collaboration. The close exchange and strong teamwork made this project a success in a very short time. Thank you for the refreshing meetings, the personal visits to my workshop, and the warm welcome at the booth.

🌊 Freudenberg – Manufacturer of Hygienic Seals

https://www.fst.com/

🎬 Behind the Scenes – Exhibition Model Production

https://ingenieur-glaser.de/hygienic-seal-demonstrator/

🧲 Customer magnets for your trade fair booth – Ooh, Aah, Wow!

Ooh – attracts visitors

Aah – makes benefits clear

Wow! – anchors brand & product

https://ingenieur-glaser.de/messebau/

#Drinktec #Freudenberg #HygienicSeals #ExhibitDesign #ExhibitionStandDesign #ExhibitionBoothDesign #ExhibitionBooth #TradeFair

#Drinktec #Freudenberg #HygienicSeals #ExhibitDesign #ExhibitionStandDesign #ExhibitionBoothDesign #ExhibitionBooth #TradeFair

Sophie Platzer

Marketing Manager

"Johannes combines creativity, design and technical know-how in one person. From planning to fabrication to the practical transport case, he implemented everything with great commitment and a lot of attention to detail. Thank you for the extremely professional collaboration!"

The trade fair exhibit at the drinktec trade show in Munich

At the drinktec trade show in Munich, the Hygienic Seal Demonstrator draws visitors to Freudenberg's booth. Under UV light, it becomes visible how crucial hygienic seals are for purity and process safety.